Tractatenblad van het Koninkrijk der Nederlanden

| Datum publicatie | Organisatie | Jaargang en nummer | Rubriek | Datum totstandkoming |

|---|---|---|---|---|

| Ministerie van Buitenlandse Zaken | Tractatenblad 2008, 87 | Verdrag |

Zoals vergunningen, bouwplannen en lokale regelgeving.

Adressen en contactpersonen van overheidsorganisaties.

U bent hier:

| Datum publicatie | Organisatie | Jaargang en nummer | Rubriek | Datum totstandkoming |

|---|---|---|---|---|

| Ministerie van Buitenlandse Zaken | Tractatenblad 2008, 87 | Verdrag |

Internationaal Verdrag voor de beveiliging van mensenlevens op zee, 1974;

(met Bijlage)

Londen, 1 november 1974

De Engelse en de Franse tekst van Verdrag en Bijlage zijn geplaatst in Trb. 1976, 157.

Voor correcties van de Bijlage zie Trb. 1983, 32.

Voor wijzigingen van de Bijlage zie Trb. 1983, 32 en rubriek J van Trb. 1983, 173, Trb. 1985, 155, Trb. 1989, 42 en 98, Trb. 1992, 24, Trb. 1994, 19, Trb. 1996, 18, 128 en 257, Trb. 1997, 226, Trb. 1998, 155, en Trb. 2005, 55.

Voor correcties van de wijzigingen van de Bijlage zie Trb. 1985, 155, rubriek J van Trb. 1995, 236, rubriek B van Trb. 1996, 128, rubriek J van Trb. 2005, 55 en rubriek B van Trb. 2006, 72.

Resolutie MSC.151(78) van 20 mei 2004

Bij Resolutie MSC.151(78) heeft de Maritieme Veiligheidscommissie van de Internationale Maritieme Organisatie op 20 mei 2004 in overeenstemming met artikel VIII(b)(iv) van het Verdrag wijzigingen aangenomen. De Engelse tekst1) van de Resolutie en de wijzigingen luidt als volgt:

(adopted on 20 May 2004)

Adoption of Amendments to the International Convention for the Safety of Life at Sea, 1974, as amended

The Maritime Safety Committee,

Recalling Article 28(b) of the Convention on the International Maritime Organization concerning the functions of the Committee,

Recalling further article VIII(b) of the International Convention for the Safety of Life at Sea (SOLAS), 1974 (hereinafter referred to as “the Convention”), concerning the amendment procedure applicable to the Annex to the Convention, other than to the provisions of chapter I thereof,

Noting SOLAS regulation II-1/3-6 concerning access to and within spaces in the cargo area of oil tankers of 500 gross tonnage and over and bulk carriers of 20,000 gross tonnage and over, adopted by resolution MSC.134(76), which is applicable to oil tankers and bulk carriers constructed on or after 1 January 2005,

Acknowledging concerns expressed with regard to problems which might be encountered when implementing the requirements of the aforementioned SOLAS regulation II-1/3-6,

Having considered, at its seventy-eighth session, amendments to SOLAS regulation II-1/3-6, proposed and circulated in accordance with article VIII(b)(i) of the Convention,

1. Adopts, in accordance with article VIII(b)(iv) of the Convention, amendments to regulation II-1/3-6 of the Convention, the text of which is set out in the Annex to the present resolution;

2. Determines, in accordance with article VIII(b)(vi)(2)(bb) of the Convention, that the said amendments shall be deemed to have been accepted on 1 July 2005, unless, prior to that date, more than one third of the Contracting Governments to the Convention or Contracting Governments the combined merchant fleets of which constitute not less than 50% of the gross tonnage of the world’s merchant fleet, have notified their objections to the amendments;

3. Invites SOLAS Contracting Governments to note that, in accordance with article VIII(b)(vii)(2) of the Convention, the amendments shall enter into force on 1 January 2006 upon their acceptance in accordance with paragraph 2 above;

4. Requests the Secretary-General, in conformity with article VIII(b)(v) of the Convention, to transmit certified copies of the present resolution and the text of the amendments contained in the Annex to all Contracting Governments to the Convention;

5. Further requests the Secretary-General to transmit copies of this resolution and its Annex to Members of the Organization, which are not Contracting Governments to the Convention;

6. Resolves that SOLAS Contracting Governments may apply, in advance, the annexed SOLAS regulation II-1/3-6 adopted by this resolution together with the amendments to the Technical provisions for means of access for inspections adopted by resolution MSC.158(78) in lieu of SOLAS regulation II-1/3-6 adopted by resolution MSC.134(76) and the Technical provisions for means of access for inspections adopted by resolution MSC.133(76) to ships flying their flag constructed on or after 1 January 2005.

1. The title of the regulation is replaced by the following:

“Access to and within spaces in, and forward of, the cargo area of oil tankers and bulk carriers”

2. In paragraph 1.1, the date “1 January 2005” is replaced with “1 January 2006”.

3. In paragraph 2.1, in the first sentence, the words “within the cargo area” and “a permanent” are deleted.

4. In paragraph 3.1, in the second sentence, the words “or to foreward ballast tanks” are inserted between the words “bottom spaces” and “may be from a pump-room”.

5. In paragraph 4.1, in the second sentence, the words “in the cargo area” are deleted.

Resolutie MSC.152(78) van 20 mei 2004

Bij Resolutie MSC.152(78) heeft de Maritieme Veiligheidscommissie van de Internationale Maritieme Organisatie op 20 mei 2004 in overeenstemming met artikel VIII(b)(iv) van het Verdrag wijzigingen aangenomen. De Engelse tekst1) van de Resolutie en de wijzigingen luidt als volgt:

(adopted on 20 May 2004)

Adoption of Amendments to the International Convention for the Safety of Life at Sea, 1974, as amended

The Maritime Safety Committee,

Recalling Article 28(b) of the Convention on the International Maritime Organization concerning the functions of the Committee,

Recalling further article VIII(b) of the International Convention for the Safety of Life at Sea (SOLAS), 1974 (hereinafter referred to as “the Convention”), concerning the amendment procedure applicable to the Annex to the Convention, other than the provisions of chapter I thereof,

Having considered, at its seventy-eighth session, amendments to the Convention, proposed and circulated in accordance with article VIII(b)(i) thereof,

1. Adopts, in accordance with article VIII(b)(iv) of the Convention, amendments to the Convention, the text of which is set out in the Annex to the present resolution;

2. Determines, in accordance with article VIII(b)(vi)(2)(bb) of the Convention, that the said amendments shall be deemed to have been accepted on 1 January 2006, unless, prior to that date, more than one third of the Contracting Governments to the Convention or Contracting Governments the combined merchant fleets of which constitute not less than 50% of the gross tonnage of the world’s merchant fleet, have notified their objections to the amendments;

3. Invites SOLAS Contracting Governments to note that, in accordance with article VIII(b)(vii)(2) of the Convention, the amendments shall enter into force on 1 July 2006 upon their acceptance in accordance with paragraph 2 above;

4. Requests the Secretary-General, in conformity with article VIII(b)(v) of the Convention, to transmit certified copies of the present resolution and the text of the amendments contained in the Annex to all Contracting Governments to the Convention;

5. Further requests the Secretary-General to transmit copies of this resolution and its Annex to Members of the Organization, which are not Contracting Governments to the Convention.

1. The existing text of paragraph 3.3.3 is replaced by the following:

“3.3.3. Except as provided in paragraphs 3.3.4 and 3.3.5, each lifeboat shall be launched, and manoeuvred in the water by its assigned operating crew, at least once every three months during an abandon ship drill.”

2. In paragraph 1, in the second sentence, the words “paragraphs 3 and 6.2” are replaced by the words “paragraphs 3.2, 3.3 and 6.2”.

3. The existing text of paragraph 3 is replaced by the following:

“3. Maintenance

3.1. Maintenance, testing and inspections of life–saving appliances shall be carried out based on the guidelines developed by the Organization1) and in a manner having due regard to ensuring reliability of such appliances.

3.2. Instructions for on-board maintenance of life-saving appliances complying with regulation 36 shall be provided and maintenance shall be carried out accordingly.

3.3. The Administration may accept, in compliance with the requirements of paragraph 3.2, a shipboard planned maintenance programme, which includes the requirements of regulation 36.”

4. The existing text of paragraph 6 is replaced by the following:

“6. Weekly inspection

The following tests and inspections shall be carried out weekly and a report of the inspection shall be entered in the log-book:

.1. all survival craft, rescue boats and launching appliances shall be visually inspected to ensure that they are ready for use. The inspection shall include, but is not limited to, the condition of hooks, their attachment to the lifeboat and the on-load release gear being properly and completely reset;

.2. all engines in lifeboats and rescue boats shall be run for a total period of not less than 3 min, provided the ambient temperature is above the minimum temperature required for starting and running the engine. During this period of time, it should be demonstrated that the gear box and gear box train are engaging satisfactorily. If the special characteristics of an outboard motor fitted to a rescue boat would not allow it to be run other than with its propeller submerged for a period of 3 min, it should be run for such a period as prescribed in the manufacturer’s handbook. In special cases, the Administration may waive this requirement for ships constructed before 1 July 1986;

.3. lifeboats, except free-fall lifeboats, on cargo ships shall be moved from their stowed position, without any persons on board, to the extent necessary to demonstrate satisfactory operation of launching appliances, if weather and sea conditions so allow; and

.4. the general emergency alarm shall be tested.”

5. In paragraph 7, the existing text is numbered as paragraph 7.2 and the following new paragraph 7.1 is added:

“7.1. All lifeboats, except free-fall lifeboats, shall be turned out from their stowed position, without any persons on board if weather and sea conditions so allow.”

6. The existing text of paragraph 11 is replaced by the following:

“11. Periodic servicing of launching appliances and on-load release gear

11.1. Launching appliances shall be:

.1. maintained in accordance with instructions for on-board maintenance as required by regulation 36;

.2. subject to a thorough examination at the annual surveys required by regulations I/7 or I/8, as applicable; and

.3. upon completion of the examination referred to in .2 subjected to a dynamic test of the winch brake at maximum lowering speed. The load to be applied shall be the mass of the lifeboat without persons on board, except that, at intervals not exceeding five years, the test shall be carried out with a proof load of 1.1 times the maximum working load of the winch.

11.2. Lifeboat on-load release gear shall be:

.1. maintained in accordance with instructions for on-board maintenance as required by regulation 36;

.2. subject to a thorough examination and operational test during the annual surveys required by regulations I/7 and I/8 by properly trained personnel familiar with the system; and

.3. operationally tested under a load of 1.1 times the total mass of the lifeboat when loaded with its full complement of persons and equipment whenever the release gear is overhauled. Such over-hauling and test shall be carried out at least once every five years.2) ”

7. The existing text of paragraph 3 is replaced by the following:

“3. Immersion suits

3.1. This paragraph applies to all cargo ships. However, with respect to cargo ships constructed before 1 July 2006, paragraphs 3.2 to 3.5 shall be complied with not later than the first safety equipment survey on or after 1 July 2006.

3.2. An immersion suit complying with the requirements of section 2.3 of the Code shall be provided for every person on board the ship. However, for ships other than bulk carriers, as defined in regulation IX/1, these immersion suits need not be required if the ship is constantly engaged on voyages in warm climates3) where, in the opinion of the Administration, immersion suits are unnecessary.

3.3. If a ship has any watch or work stations which are located remotely from the place or places where immersion suits are normally stowed, additional immersion suits shall be provided at these locations for the number of persons normally on watch or working at those locations at any time.

3.4. Immersion suits shall be so placed as to be readily accessible and their position shall be plainly indicated.

3.5. The immersion suits required by this regulation may be used to comply with the requirements of regulation 7.3.”

8. The existing text of paragraph 9 is replaced by the following:

“9. Satellite EPIRBs shall be:

.1. annually tested for all aspects of operational efficiency, with special emphasis on checking the emission on operational frequencies, coding and registration, at intervals as specified below:

.1. on passenger ships, within 3 months before the expiry date of the Passenger Ship Safety Certificate; and

.2. on cargo ships, within 3 months before the expiry date, or 3 months before or after the anniversary date, of the Cargo Ship Safety Radio Certificate.

The test may be conducted on board the ship or at an approved testing station; and

.2. subject to maintenance at intervals not exceeding five years, to be performed at an approved shore-based maintenance facility.”

Resolutie MSC.153(78) van 20 mei 2004

Bij Resolutie MSC.153(78) heeft de Maritieme Veiligheidscommissie van de Internationale Maritieme Organisatie op 20 mei 2004 in overeenstemming met artikel VIII(b)(iv) van het Verdrag wijzigingen aangenomen. De Engelse tekst1) van de Resolutie en de wijzigingen luidt als volgt:

(adopted on 20 May 2004)

Adoption of Amendments to the International Convention for the Safety of Life at Sea, 1974, as amended

The Maritime Safety Committee,

Recalling Article 28(b) of the Convention on the International Maritime Organization concerning the functions of the Committee,

Recalling further article VIII(b) of the International Convention for the Safety of Life at Sea (SOLAS), 1974 (hereinafter referred to as “the Convention”) concerning the amendment procedure applicable to the Annex to the Convention, other than the provisions of chapter I thereof,

Noting resolution A.920(22) entitled “Review of safety measures and procedures for the treatment of persons rescued at sea”,

Recalling also the provisions of the Convention relating to the obligation of:

– shipmasters to proceed with all speed to the assistance of persons in distress at sea; and

– Contracting Governments to ensure arrangements for coast watching and for the rescue of persons in distress at sea round their coasts,

Noting also article 98 of the United Nations Convention on the Law of the Sea, 1982, regarding the duty to render assistance,

Noting further the initiative taken by the Secretary-General to involve competent United Nations specialized agencies and programmes in the consideration of the issues addressed in this resolution, for the purpose of agreeing on a common approach which will resolve them in an efficient and consistent manner,

Realizing the need for clarification of existing procedures to guarantee that persons rescued at sea will be provided a place of safety regardless of their nationality, status or the circumstances in which they are found,

Realizing further that the intent of the new paragraph 1-1 of SOLAS regulation V/33, as adopted by this resolution, is to ensure that in every case a place of safety is provided within a reasonable time. It is further intended that the responsibility to provide a place of safety, or to ensure that a place of safety is provided, falls on the Contracting Government responsible for the search and rescue region in which the survivors were recovered,

Having considered, at its seventy-eighth session, amendments to the Convention, proposed and circulated in accordance with article VIII(b)(i) thereof,

1. Adopts, in accordance with article VIII(b)(iv) of the Convention, amendments to the Convention, the text of which is set out in the Annex to the present resolution;

2. Determines, in accordance with article VIII(b)(vi)(2)(bb) of the Convention, that the said amendments shall be deemed to have been accepted on 1 January 2006, unless, prior to that date, more than one third of the Contracting Governments to the Convention or Contracting Governments the combined merchant fleets of which constitute not less than 50% of the gross tonnage of the world’s merchant fleet, have notified their objections to the amendments;

3. Invites SOLAS Contracting Governments to note that, in accordance with article VIII(b)(vii)(2) of the Convention, the amendments shall enter into force on 1 July 2006 upon their acceptance in accordance with paragraph 2 above;

4. Requests the Secretary-General, in conformity with article VIII(b)(v) of the Convention, to transmit certified copies of the present resolution and the text of the amendments contained in the Annex to all Contracting Governments to the Convention;

5. Further requests the Secretary-General to transmit copies of this resolution and its Annex to Members of the Organization, which are not Contracting Governments to the Convention;

6. Also requests the Secretary General to take appropriate action in further pursuing his inter-agency initiative, informing the Maritime Safety Committee of developments, in particular with respect to procedures to assist in the provision of places of safety for persons in distress at sea, for action as the Committee may deem appropriate.

1. The following new paragraph 5 is added after the existing paragraph 4:

“5. Search and rescue service. The performance of distress monitoring, communication, co-ordination and search and rescue functions, including provision of medical advice, initial medical assistance, or medical evacuation, through the use of public and private resources including co-operating aircraft, ships, vessels and other craft and installations.”

2. The title of the regulation is replaced by the following:

“Distress situations: obligations and procedures”

3. In paragraph 1, the words “a signal” in the first sentence are replaced by the word “information”, and the following sentence is added after the first sentence of the paragraph:

“This obligation to provide assistance applies regardless of the nationality or status of such persons or the circumstances in which they are found.”

4. The following new paragraph 1-1 is inserted after the existing paragraph 1:

“1-1. Contracting Governments shall co-ordinate and co-operate to ensure that masters of ships providing assistance by embarking onboard persons in distress at sea are released from their obligations with minimum further deviation from the ships’ intended voyage, provided that releasing the master of the ship from the obligations under the current regulation does not further endanger the safety of life at sea. The Contracting Government responsible for the search and rescue region in which such assistance is rendered shall exercise primary responsibility for ensuring such co-ordination and co-operation occurs, so that survivors assisted are disembarked from the assisting ship and delivered to a place of safety, taking into account the particular circumstances of the case and guidelines developed by the Organization. In these cases the relevant Contracting Governments shall arrange for such disembarkation to be effected as soon as reasonably practicable.”

5. The following new paragraph 6 is added after the existing paragraph 5:

“6. Masters of ships who have embarked persons in distress at sea shall treat them with humanity, within the capabilities and limitations of the ship.”

6. The existing paragraph 3 is deleted.

7. The following new regulation 34-1 is added after the existing regulation 34:

The owner, the charterer, the company operating the ship as defined in regulation IX/1, or any other person shall not prevent or restrict the master of the ship from taking or executing any decision which, in the master’s professional judgement, is necessary for safety of life at sea and protection of the marine environment.”

Resolutie MSC.170(79) van 9 december 2004

Bij Resolutie MSC.170(79) heeft de Maritieme Veiligheidscommissie van de Internationale Maritieme Organisatie op 9 december 2004 in overeenstemming met artikel VIII(b)(iv) van het Verdrag wijzigingen aangenomen. De Engelse tekst1) van de Resolutie en de wijzigingen luidt als volgt:

(adopted on 9 December 2004)

Adoption of Amendments to the International Convention for the Safety of Life at Sea, 1974, as amended

The Maritime Safety Committee,

Recalling Article 28(b) of the Convention on the International Maritime Organization concerning the functions of the Committee,

Recalling further article VIII(b) of the International Convention for the Safety of Life at Sea (SOLAS), 1974 (hereinafter referred to as “the Convention”), concerning the amendment procedure applicable to the Annex to the Convention, other than the provisions of chapter I thereof,

Having considered, at its seventy-ninth session, amendments to the Convention, proposed and circulated in accordance with article VIII(b)(i) thereof,

1. Adopts, in accordance with article VIII(b)(iv) of the Convention, amendments to the Convention, the text of which is set out in the Annex to the present resolution;

2. Determines, in accordance with article VIII(b)(vi)(2)(bb) of the Convention, that the said amendments shall be deemed to have been accepted on 1 January 2006, unless, prior to that date, more than one third of the Contracting Governments to the Convention or Contracting Governments the combined merchant fleets of which constitute not less than 50% of the gross tonnage of the world’s merchant fleet, have notified their objections to the amendments;

3. Invites SOLAS Contracting Governments to note that, in accordance with article VIII(b)(vii)(2) of the Convention, the amendments shall enter into force on 1 July 2006 upon their acceptance in accordance with paragraph 2 above;

4. Requests the Secretary-General, in conformity with article VIII(b)(v) of the Convention, to transmit certified copies of the present resolution and the text of the amendments contained in the Annex to all Contracting Governments to the Convention;

5. Further requests the Secretary-General to transmit copies of this resolution and its Annex to Members of the Organization, which are not Contracting Governments to the Convention.

1. The following new paragraph 14 is added after existing paragraph 13:

“14. Bulk carrier means a bulk carrier as defined in regulation XII/1.1.”

2. Paragraph 2 of the regulation is replaced by the following:

“2. In passenger ships and cargo ships watertight doors shall be tested by water pressure to a head up to the bulkhead deck or freeboard deck respectively. Where testing of individual doors is not carried out because of possible damage to insulation or outfitting items, testing of individual doors may be replaced by a prototype pressure test of each type and size of door with a test pressure corresponding at least to the head required for the intended location. The prototype test shall be carried out before the door is fitted. The installation method and procedure for fitting the door on board shall correspond to that of the prototype test. When fitted on board, each door shall be checked for proper seating between the bulkhead, the frame and the door.”

3. After the heading the following words are added:

“(Paragraphs 10 and 11 of this regulation apply to ships constructed on or after 1 January 2007)”.

4. Existing paragraph 10 is replaced by the following:

“10. No electrical equipment shall be installed in any space where flammable mixtures are liable to collect, e.g. in compartments assigned principally to accumulator batteries, in paint lockers, acetylene stores or similar spaces, unless the Administration is satisfied that such equipment is:

.1. essential for operational purposes;

.2. of a type which will not ignite the mixture concerned;

.3. appropriate to the space concerned; and

.4. appropriately certified for safe usage in the dusts, vapours or gases likely to be encountered.”

5. The following new paragraph 11 is added after paragraph 10, as amended:

“11. In tankers, electrical equipment, cables and wiring shall not be installed in hazardous locations unless it conforms with standards not inferior to those acceptable to the Organization1) . However, for locations not covered by such standards, electrical equipment, cables and wiring which do not conform to the standards may be installed in hazardous locations based on a risk assessment to the satisfaction of the Administration, to ensure that an equivalent level of safety is assured.”

6. Existing paragraph 11 is renumbered as paragraph 12.

7. The following new paragraph 1.8 is added after existing paragraph 1.7:

“1.8. Notwithstanding the requirements of paragraph 1.1, bulk carriers as defined in regulation IX/1.6 constructed on or after 1 July 2006 shall comply with the requirements of paragraph 1.2.”

8. In paragraph 2.5, the existing text of subparagraph .1 is replaced by the following:

“.1. a gyro compass, or other means, to determine and display their heading by shipborne non-magnetic means, being clearly readable by the helmsman at the main steering position. These means shall also transmit heading information for input to the equipment referred in paragraphs 2.3.2, 2.4 and 2.5.5;”

9. The following new paragraph 2 is added after existing paragraph 1:

“2. To assist in casualty investigations, cargo ships, when engaged on international voyages, shall be fitted with a VDR which may be a simplified voyage data recorder (S-VDR)2) as follows:

.1. in the case of cargo ships of 20,000 gross tonnage and upwards constructed before 1 July 2002, at the first scheduled dry-docking after 1 July 2006 but not later than 1 July 2009;

.2. in the case of cargo ships of 3,000 gross tonnage and upwards but less than 20,000 gross tonnage constructed before 1 July 2002, at the first scheduled dry-docking after 1 July 2007 but not later than 1 July 2010; and

.3. Administrations may exempt cargo ships from the application of the requirements of subparagraphs .1 and .2 when such ships will be taken permanently out of service within two years after the implementation date specified in subparagraphs .1 and .2 above.”

10. Existing paragraph 2 is renumbered as paragraph 3.

11. The following sentence is deleted from paragraph 1 of the regulation:

“For the purpose of this regulation, the requirements of the Code shall be treated as mandatory.”

12. The existing text of chapter XII is replaced by the following:

For the purpose of this chapter:

1. Bulk carrier means a ship which is intended primarily to carry dry cargo in bulk, including such types as ore carriers and combination carriers3) .

2. Bulk carrier of single-side skin construction means a bulk carrier as defined in paragraph 1, in which:

.1. any part of a cargo hold is bounded by the side shell; or

.2. one or more cargo holds are bounded by a double-side skin, the width of which is less than 760 mm in bulk carriers constructed before 1 January 2000 and less than 1,000 mm in bulk carriers constructed on or after 1 January 2000 but before 1 July 2006, the distance being measured perpendicular to the side shell.

Such ships include combination carriers in which any part of a cargo hold is bounded by the side shell.

3. Bulk carrier of double-side skin construction means a bulk carrier as defined in paragraph 1, in which all cargo holds are bounded by a double-side skin, other than as defined in paragraph 2.2.

4. Double-side skin means a configuration where each ship side is constructed by the side shell and a longitudinal bulkhead connecting the double bottom and the deck. Hopper side tanks and top-side tanks may, where fitted, be integral parts of the double-side skin configuration.

5. Length of a bulk carrier means the length as defined in the International Convention on Load Lines in force.

6. Solid bulk cargo means any material, other than liquid or gas, consisting of a combination of particles, granules or any larger pieces of material, generally uniform in composition, which is loaded directly into the cargo spaces of a ship without any intermediate form of containment.

7. Bulk carrier bulkhead and double bottom strength standards means “Standards for the evaluation of scantlings of the transverse watertight vertically corrugated bulkhead between the two foremost cargo holds and for the evaluation of allowable hold loading of the foremost cargo hold” adopted by resolution 4 of the Conference of Contracting Governments to the International Convention for the Safety of Life at Sea, 1974 on 27 November 1997, as may be amended by the Organization, provided that such amendments are adopted, brought into force and take effect in accordance with the provisions of article VIII of the present Convention concerning the amendment procedures applicable to the Annex other than chapter I.

8. Bulk carriers constructed means bulk carriers the keels of which are laid or which are at a similar stage of construction.

9. A similar stage of construction means the stage at which:

.1. construction identifiable with a specific ship begins; and

.2. assembly of that ship has commenced comprising at least 50 tonnes or one per cent of the estimated mass of all structural material, whichever is less.

10. Breadth (B) of a bulk carrier means the breadth as defined in the International Convention on Load Lines in force.

Bulk carriers shall comply with the requirements of this chapter in addition to the applicable requirements of other chapters.

Bulk carriers constructed before 1 July 1999 to which regulations 4 or 6 apply shall comply with the provisions of such regulations according to the following schedule, with reference to the enhanced programme of inspections required by regulation XI-1/2:

.1. bulk carriers, which are 20 years of age and over on 1 July 1999, by the date of the first intermediate survey or the first periodical survey after 1 July 1999, whichever comes first;

.2. bulk carriers, which are 15 years of age and over but less than 20 years of age on 1 July 1999, by the date of the first periodical survey after 1 July 1999, but not later than 1 July 2002; and

.3. bulk carriers, which are less than 15 years of age on 1 July 1999, by the date of the first periodical survey after the date on which the ship reaches 15 years of age, but not later than the date on which the ship reaches 17 years of age.

1. Bulk carriers of 150 m in length and upwards of single-side skin construction, designed to carry solid bulk cargoes having a density of 1,000 kg/m3 and above, constructed on or after 1 July 1999, shall, when loaded to the summer load line, be able to withstand flooding of any one cargo hold in all loading conditions and remain afloat in a satisfactory condition of equilibrium, as specified in paragraph 4.

2. Bulk carriers of 150 m in length and upwards of double-side skin construction in which any part of longitudinal bulkhead is located within B/5 or 11.5 m, whichever is less, inboard from the ship’s side at right angle to the centreline at the assigned summer load line, designed to carry solid bulk cargoes having a density of 1,000 kg/m3 and above, constructed on or after 1 July 2006, shall, when loaded to the summer load line, be able to withstand flooding of any one cargo hold in all loading conditions and remain afloat in a satisfactory condition of equilibrium, as specified in paragraph 4.

3. Bulk carriers of 150 m in length and upwards of single-side skin construction, carrying solid bulk cargoes having a density of 1,780 kg/m3 and above, constructed before 1 July 1999 shall, when loaded to the summer load line, be able to withstand flooding of the foremost cargo hold in all loading conditions and remain afloat in a satisfactory condition of equilibrium, as specified in paragraph 4. This requirement shall be complied with in accordance with the implementation schedule specified in regulation 3.

4. Subject to the provisions of paragraph 7, the condition of equilibrium after flooding shall satisfy the condition of equilibrium laid down in the annex to resolution A.320(IX) – Regulation equivalent to regulation 27 of the International Convention on Load Lines, 1966, as amended by resolution A.514(13). The assumed flooding need only take into account flooding of the cargo hold space to the water level outside the ship in that flooded condition. The permeability of a loaded hold shall be assumed as 0.9 and the permeability of an empty hold shall be assumed as 0.95, unless a permeability relevant to a particular cargo is assumed for the volume of a flooded hold occupied by cargo and a permeability of 0.95 is assumed for the remaining empty volume of the hold.

5. Bulk carriers constructed before 1 July 1999, which have been assigned a reduced freeboard in compliance with regulation 27(7) of the International Convention on Load Lines, 1966, as adopted on 5 April 1966, may be considered as complying with paragraph 3 of this regulation.

6. Bulk carriers which have been assigned a reduced freeboard in compliance with the provisions of paragraph (8) of the regulation equivalent to regulation 27 of the International Convention on Load Lines, 1966, adopted by resolution A.320(IX), as amended by resolution A.514(13), may be considered as complying with paragraphs 1 or 2, as appropriate.

7. On bulk carriers which have been assigned reduced freeboard in compliance with the provisions of regulation 27(8) of Annex B of the Protocol of 1988 relating to the International Convention on Load Lines, 1966, the condition of equilibrium after flooding shall satisfy the relevant provisions of that Protocol.

1. Bulk carriers of 150 m in length and upwards of single-side skin construction, designed to carry solid bulk cargoes having a density of 1,000 kg/m3 and above, constructed on or after 1 July 1999, shall have sufficient strength to withstand flooding of any one cargo hold to the water level outside the ship in that flooded condition in all loading and ballast conditions, taking also into account dynamic effects resulting from the presence of water in the hold, and taking into account the recommendations adopted by the Organization.4)

2. Bulk carriers of 150 m in length and upwards of double-side skin construction, in which any part of longitudinal bulkhead is located within B/5 or 11.5 m, whichever is less, inboard from the ship’s side at right angle to the centreline at the assigned summer load line, designed to carry bulk cargoes having a density of 1,000 kg/m3 and above, constructed on or after 1 July 2006, shall comply with the structural strength provisions of paragraph 1.

1. Bulk carriers of 150 m in length and upwards of single-side skin construction, carrying solid bulk cargoes having a density of 1,780 kg/m3 and above, constructed before 1 July 1999, shall comply with the following requirements in accordance with the implementation schedule specified in regulation 3:

.1. The transverse watertight bulkhead between the two foremost cargo holds and the double bottom of the foremost cargo hold shall have sufficient strength to withstand flooding of the foremost cargo hold, taking also into account dynamic effects resulting from the presence of water in the hold, in compliance with the Bulk carrier bulkhead and double bottom strength standards. For the purpose of this regulation, the Bulk carrier bulkhead and double bottom strength standards shall be treated as mandatory.

.2. In considering the need for, and the extent of, strengthening of the transverse watertight bulkhead or double bottom to meet the requirements of 1.1, the following restrictions may be taken into account:

.1. restrictions on the distribution of the total cargo weight between the cargo holds; and

.2. restrictions on the maximum deadweight.

.3. For bulk carriers using either of, or both, the restrictions given in 1.2.1 and 1.2.2 above for the purpose of fulfilling the requirements of 1.1, these restrictions shall be complied with whenever solid bulk cargoes having a density of 1,780 kg/m3 and above are carried.

2. Bulk carriers of 150 m in length and upwards constructed on or after 1 July 2006, shall comply in all areas with double-side skin construction with the following requirements:

.1. Primary stiffening structures of the double-side skin shall not be placed inside the cargo hold space.

.2. Subject to the provisions below, the distance between the outer shell and the inner shell at any transverse section shall not be less than 1,000 mm measured perpendicular to the side shell. The double-side skin construction shall be such as to allow access for inspection as provided in regulation II-1/3-6 and the Technical Provisions referring thereto.

.1. The clearances below need not be maintained in way of cross ties, upper and lower end brackets of transverse framing or end brackets of longitudinal framing.

.2. The minimum width of the clear passage through the double-side skin space in way of obstructions such as piping or vertical ladders shall not be less than 600 mm.

.3. Where the inner and/or outer skins are transversely framed, the minimum clearance between the inner surfaces of the frames shall not be less than 600 mm.

.4. Where the inner and outer skins are longitudinally framed, the minimum clearance between the inner surfaces of the frames shall not be less than 800 mm. Outside the parallel part of the cargo hold length this clearance may be reduced where necessitated by the structural configuration, but shall in no case be less than 600 mm.

.5. The minimum clearance referred to above shall be the shortest distance measured between assumed lines connecting the inner surfaces of the frames on the inner and outer skins.

3. Double-side skin spaces and dedicated seawater ballast tanks arranged in bulk carriers of 150 m in length and upwards constructed on or after 1 July 2006 shall be coated in accordance with the requirements of regulation II-1/3-2 and also based on the Performance standards for coatings5) to be adopted by the Organization.

4. The double-side skin spaces, with the exception of top-side wing tanks, if fitted, shall not be used for the carriage of cargo.

5. In bulk carriers of 150 m in length and upwards, carrying solid bulk cargoes having a density of 1,000 kg/m3 and above, constructed on or after 1 July 2006:

.1. the structure of cargo holds shall be such that all contemplated cargoes can be loaded and discharged by standard loading/discharge equipment and procedures without damage which may compromise the safety of the structure;

.2. effective continuity between the side shell structure and the rest of the hull structure shall be assured; and

.3. the structure of cargo areas shall be such that single failure of one stiffening structural member will not lead to immediate consequential failure of other structural items potentially leading to the collapse of the entire stiffened panels.

1. Bulk carriers of 150 m in length and upwards of single-side skin construction, constructed before 1 July 1999, of 10 years of age and over, shall not carry solid bulk cargoes having a density of 1,780 kg/m3 and above unless they have satisfactorily undergone either:

.1. a periodical survey, in accordance with the enhanced programme of inspections during surveysrequired by regulation XI-1/2; or

.2. a survey of all cargo holds to the same extent as required for periodical surveys in the enhanced programme of inspectionsduring surveys required by regulation XI-1/2.

2. Bulk carriers shall comply with the maintenance requirements provided in regulation II-1/3-1 and the Standards for owners’ inspection and maintenance of bulk carrier hatch covers, adopted by the Organization by resolution MSC.169(79), as may be amended by the Organization, provided that such amendments are adopted, brought into force and take effect in accordance with the provisions of article VIII of the present Convention concerning the amendment procedures applicable to the Annex other than chapter I.

1. The booklet required by regulation VI/7.2 shall be endorsed by the Administration, or on its behalf, to indicate that regulations 4, 5, 6 and 7, as appropriate, are complied with.

2. Any restrictions imposed on the carriage of solid bulk cargoes having a density of 1,780 kg/m3 and above in accordance with the requirements of regulations 6 and 14 shall be identified and recorded in the booklet referred to in paragraph 1.

3. A bulk carrier to which paragraph 2 applies shall be permanently marked on the side shell at midships, port and starboard, with a solid equilateral triangle, having sides of 500 mm and its apex 300 mm below the deck line, and painted a contrasting colour to that of the hull.

For bulk carriers constructed before 1 July 1999 being within the application limits of regulation 4.3, which have been constructed with an insufficient number of transverse watertight bulkheads to satisfy that regulation, the Administration may allow relaxation from the application of regulations 4.3 and 6, on condition that they shall comply with the following requirements:

.1. for the foremost cargo hold, the inspections prescribed for the annual survey in the enhanced programme of inspections during surveys required by regulation XI-1/2 shall be replaced by the inspections prescribed therein for the intermediate survey of cargo holds;

.2. are provided with bilge well high water level alarms in all cargo holds, or in cargo conveyor tunnels, as appropriate, giving an audible and visual alarm on the navigation bridge, as approved by the Administration or an organization recognized by it in accordance with the provisions of regulation XI-1/1; and

.3. are provided with detailed information on specific cargo hold flooding scenarios. This information shall be accompanied by detailed instructions on evacuation preparedness under the provisions of section 8 of the International Safety Management (ISM) Code and be used as the basis for crew training and drills.

1. Prior to loading bulk cargo on bulk carriers of 150 m in lengthand upwards, the shipper shall declare the density of the cargo, in addition to providing the cargo information required by regulation VI/2.

2. For bulk carriers to which regulation 6 applies, unless such bulk carriers comply with all relevant requirements of this chapter applicable to the carriage of solid bulk cargoes having a density of 1,780 kg/m3 and above, any cargo declared to have a density within the range 1,250 kg/m3 to 1,780 kg/m3 shall have its density verified by an accredited testing organization.6)

1. Bulk carriers of 150 m in length and upwards shall be fitted with a loading instrument capable of providing information on hull girder shear forces and bending moments, taking into account the recommendation adopted by the Organization.7)

2. Bulk carriers of 150 m in length and upwards constructed before 1 July 1999 shall comply with the requirements of paragraph 1 not later than the date of the first intermediate or periodical survey of the ship to be carried out after 1 July 1999.

3. Bulk carriers of less than 150 m in length constructed on or after 1 July 2006 shall be fitted with a loading instrument capable of providing information on the ship’s stability in the intact condition. The computer software shall be approved for stability calculations by the Administration and shall be provided with standard conditions for testing purposes relating to the approved stability information.8)

1. Bulk carriers shall be fitted with water level detectors:

.1. in each cargo hold, giving audible and visual alarms, one when the water level above the inner bottom in any hold reaches a height of 0.5 m and anotherat a height not less than 15% of the depth of the cargo hold but not more than 2 m. On bulk carriers to which regulation 9.2 applies, detectors with only the latter alarm need be installed. The water level detectors shall be fitted in the aft end of the cargo holds. For cargo holds which are used for water ballast, an alarm overriding device may be installed. The visual alarms shall clearly discriminate between the two different water levels detected in each hold;

.2. in any ballast tank forward of the collision bulkhead required by regulation II-1/11, giving an audible and visual alarm when the liquid in the tank reaches a level not exceeding 10% of the tank capacity. An alarm overridingdevice may be installedto be activated when the tank is in use; and

.3. in any dry or void space other than a chain cable locker, any part of which extends forward of the foremost cargo hold, giving anaudible and visual alarm at a water level of 0.1 m above the deck. Such alarms need not be provided in enclosed spaces the volume ofwhich does not exceed 0.1% of the ship’s maximum displacement volume.

2. The audible and visual alarms specified in paragraph 1 shall be located on the navigationbridge.

3. Bulk carriers constructed before 1 July 2004 shall comply with the requirements of this regulation not later than the date of the annual, intermediate or renewal survey of the ship to be carried out after 1 July 2004, whichever comes first.

1. On bulk carriers, the means for draining and pumping ballasttanks forward of the collision bulkhead and bilges of dry spaces any part of which extends forward of the foremost cargo hold shall be capable of being brought into operation from a readily accessible enclosed space, the location of which is accessible from the navigation bridge or propulsion machinery control position without traversing exposed freeboard or superstructure decks. Where pipes serving such tanks or bilges pierce the collision bulkhead, valve operation by means of remotely operated actuators may be accepted, as an alternative to the valve control specified in regulation II-1/11.4, provided that the location of such valve controls complies with this regulation.

2. Bulk carriers constructed before 1 July 2004 shall comply with the requirements of this regulation not later than the date of the first intermediate or renewal survey of the ship to be carried out after 1 July 2004, but in no case later than 1 July 2007.

Bulk carriers of 150 m in length and upwards of single-side skin construction, carrying cargoes having a density of 1,780 kg/m3 and above, if not meeting the requirements for withstanding flooding of any one cargo hold as specified in regulation 5.1 and the Standards and criteria for side structures of bulk carriers of single-side skin construction, adopted by the Organization by resolution MSC.168(79), as may be amended by the Organization, provided that such amendments are adopted, brought into force and take effect in accordance with the provisions of article VIII of the present Convention concerning the amendment procedures applicable to the Annex other than chapter I, shall not sail with any hold loaded to less than 10% of the hold’s maximum allowable cargo weight when in the full load condition, after reaching 10 years of age. The applicable full load condition for this regulation is a load equal to or greater than 90% of the ship’s deadweight at the relevant assigned freeboard.”

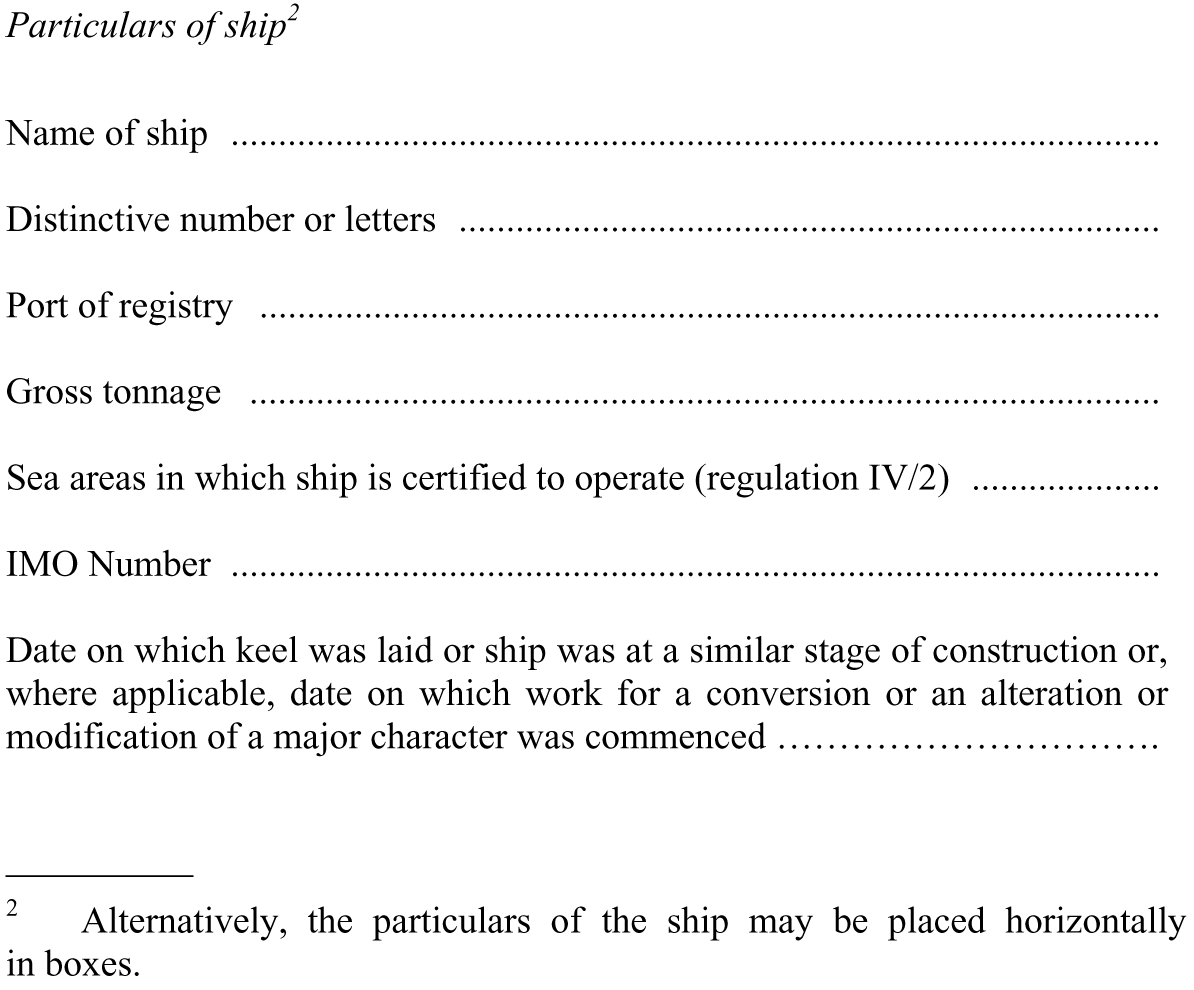

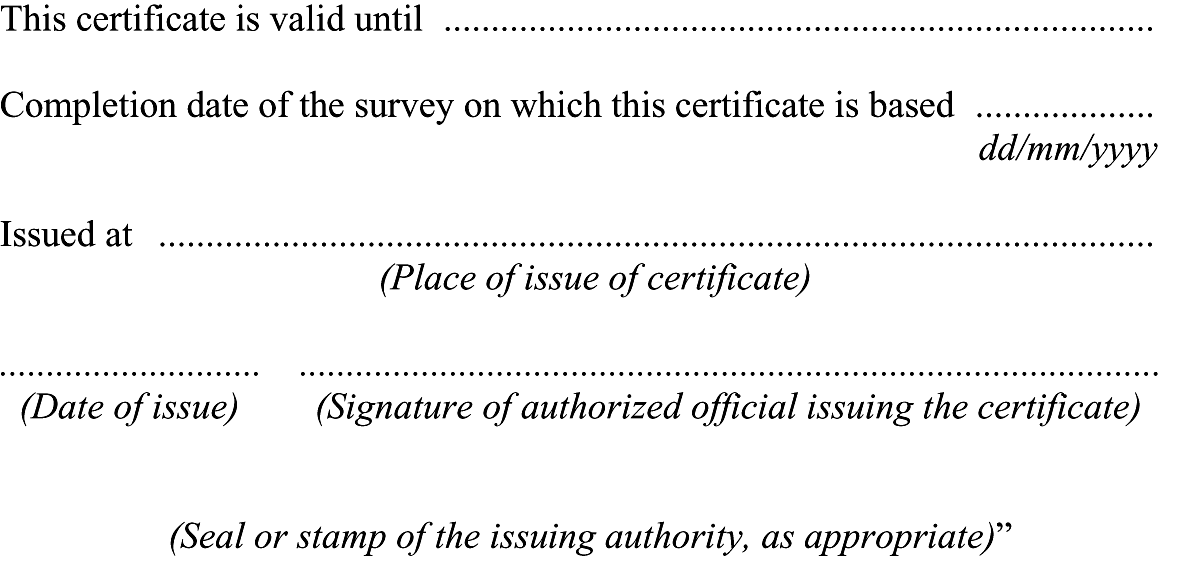

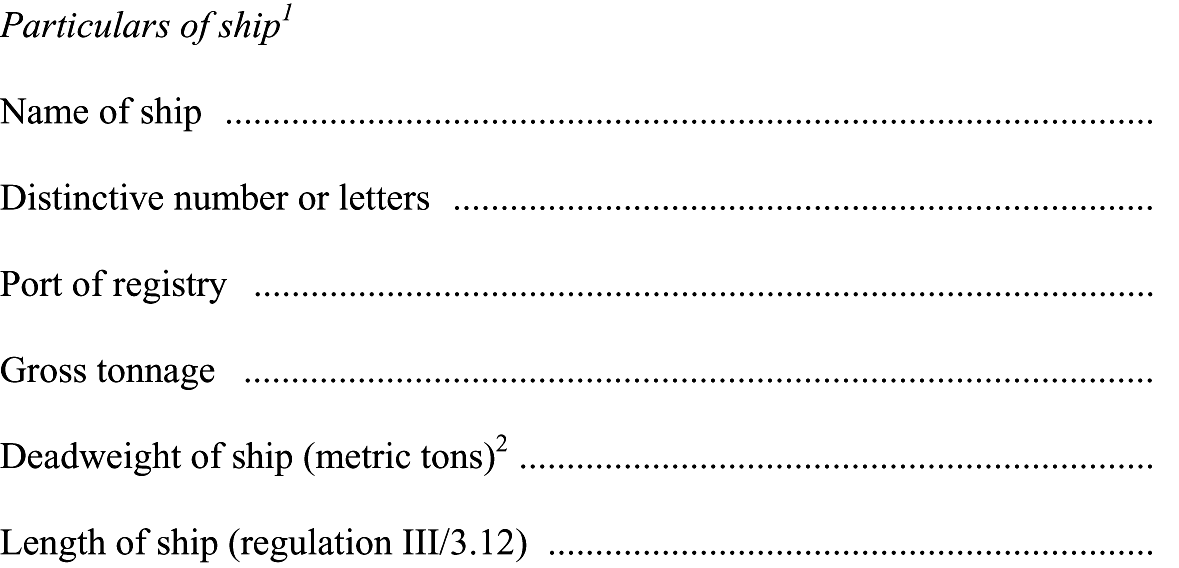

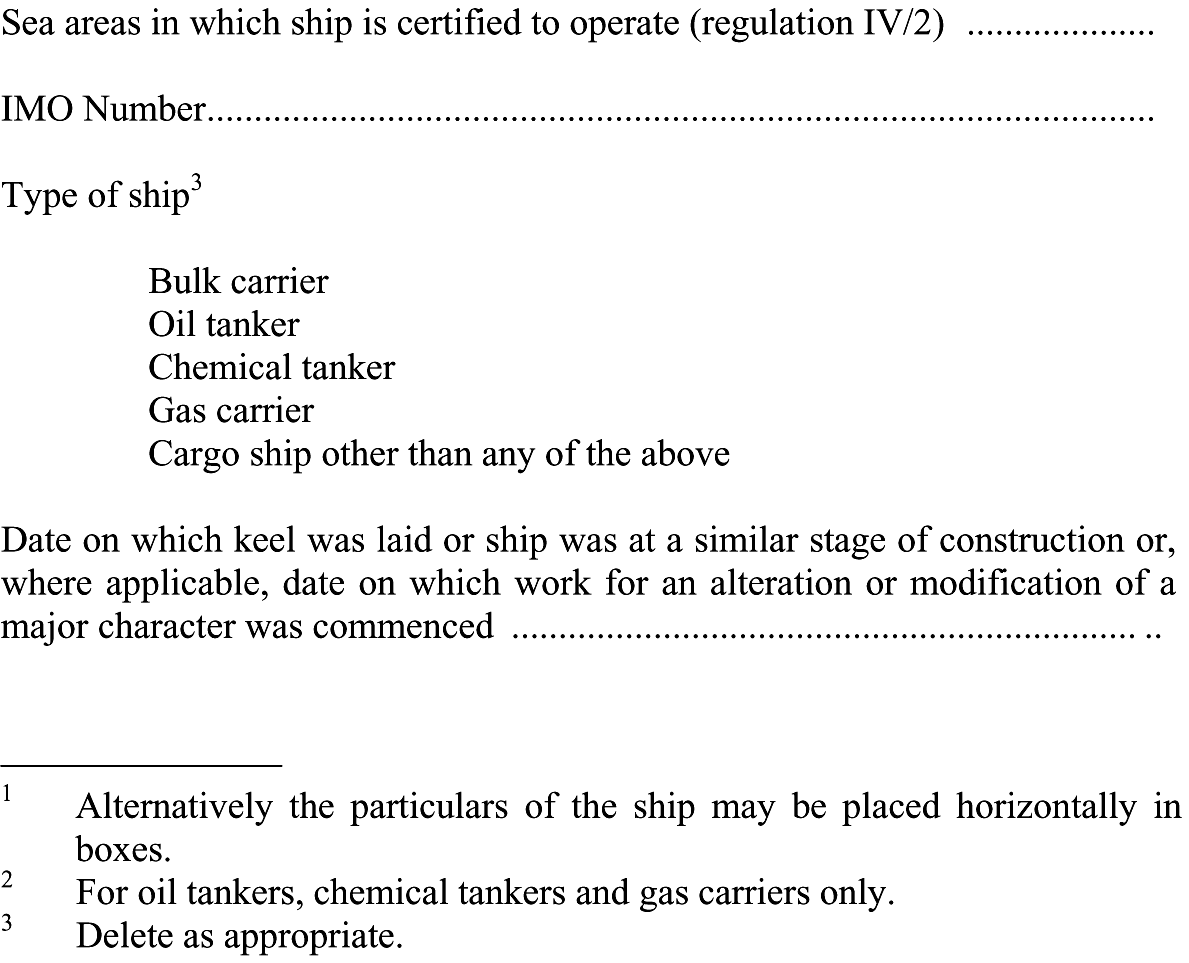

13. The following new section is inserted between the section commencing with the words “This certificate is valid until” and the section commencing with the words “Issued at”:

14. The following new section is inserted between the section commencing with the words “This certificate is valid until” and the section commencing with the words “Issued at”:

15. The following new section is inserted between the section commencing with the words “This certificate is valid until” and the section commencing with the words “Issued at”:

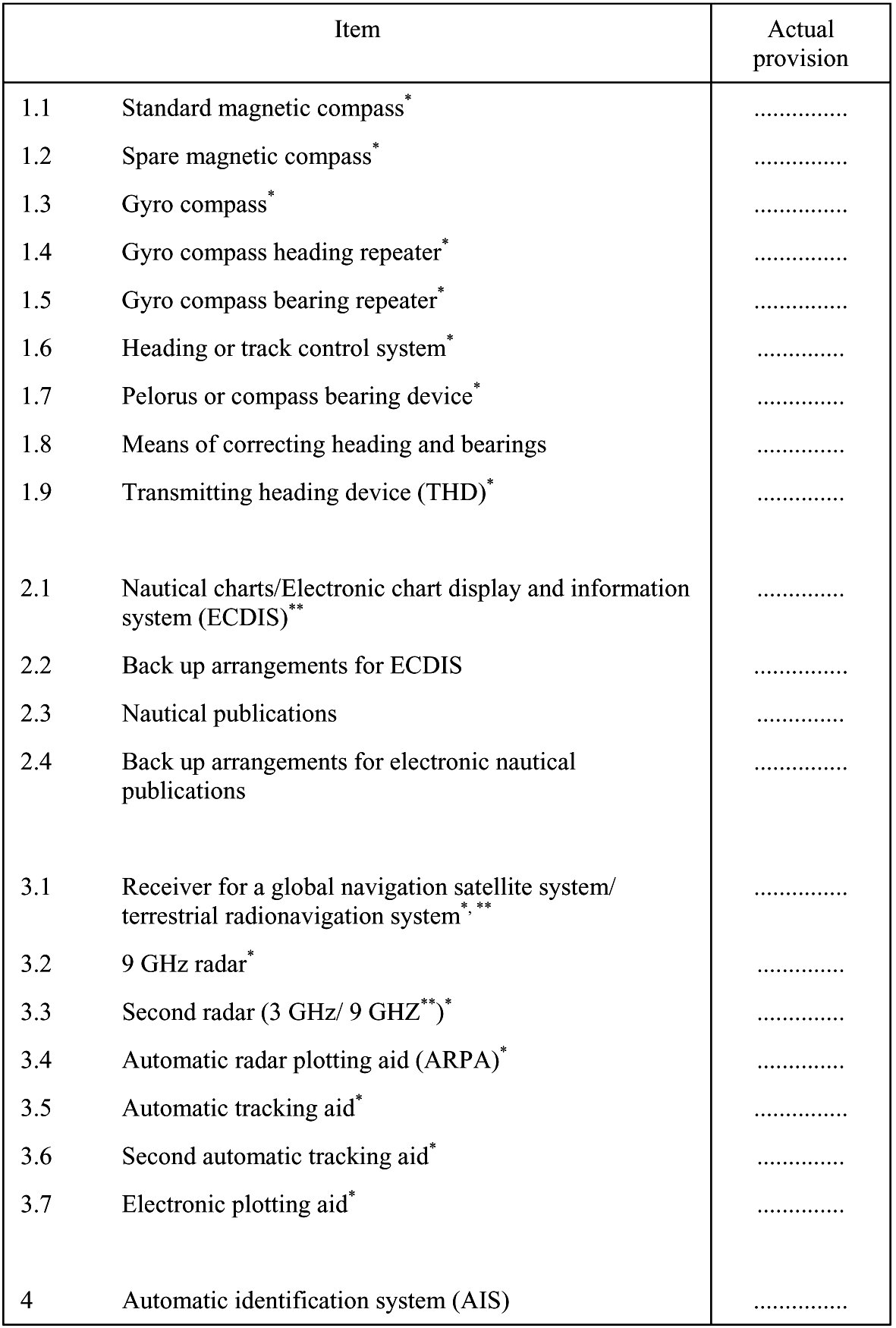

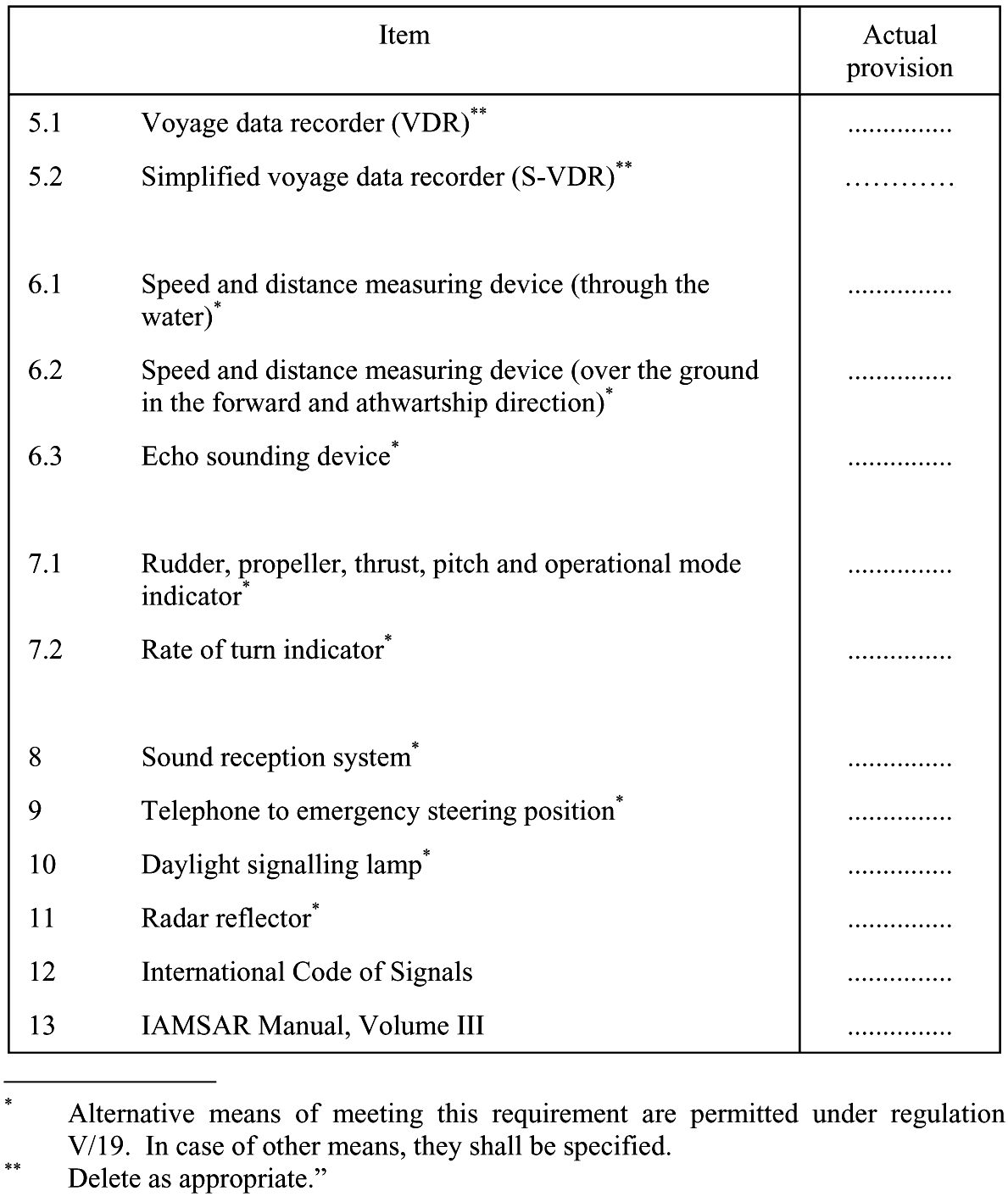

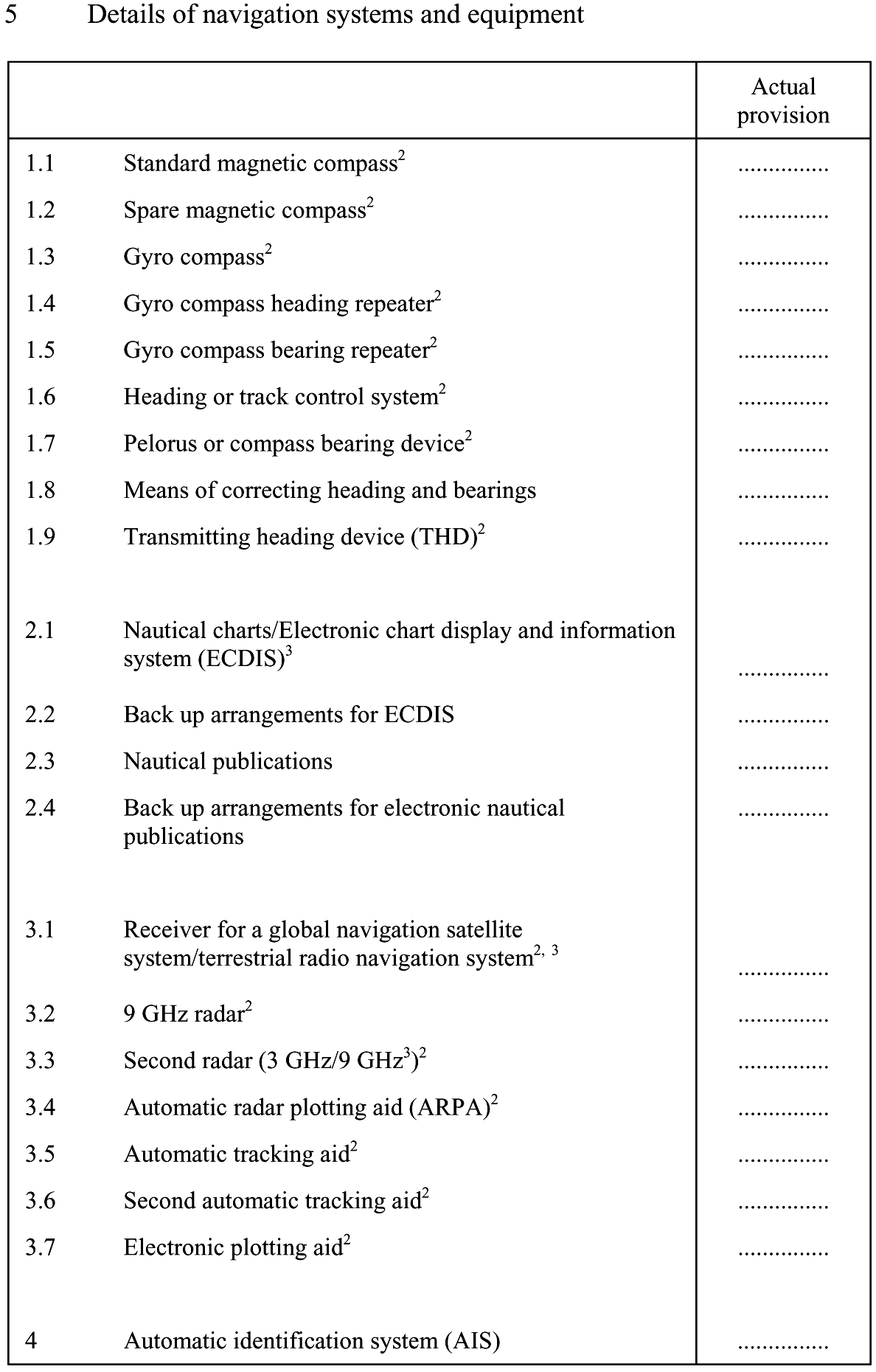

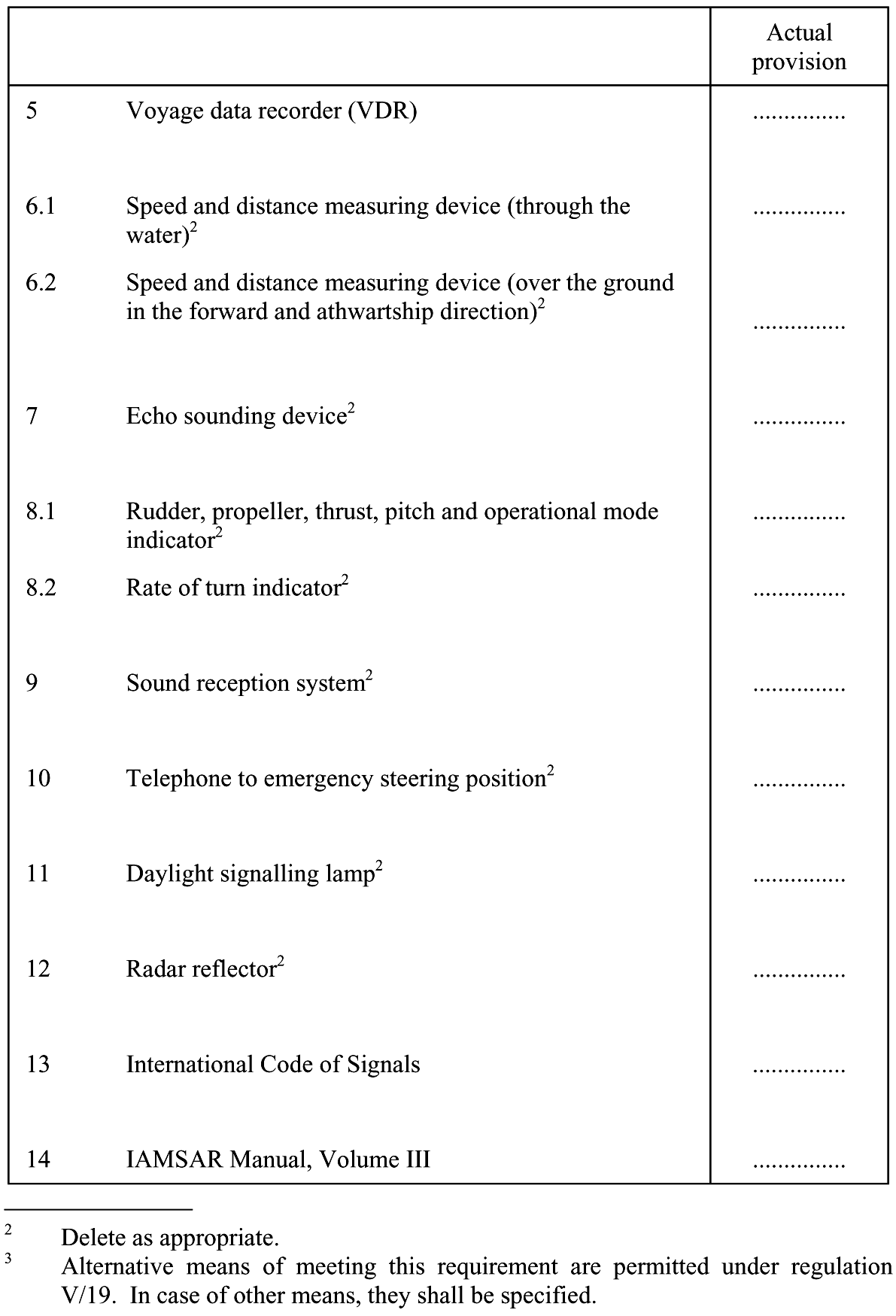

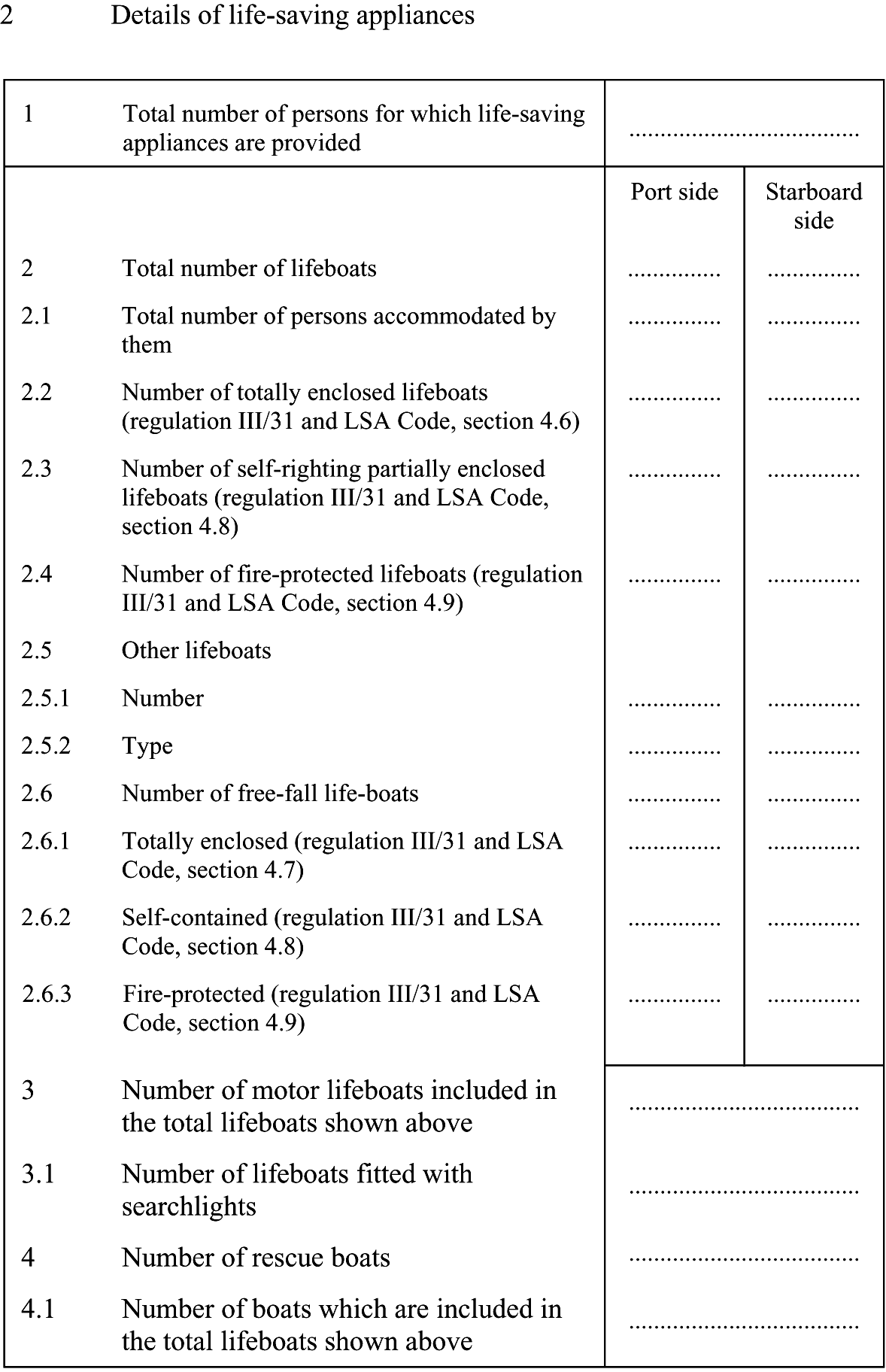

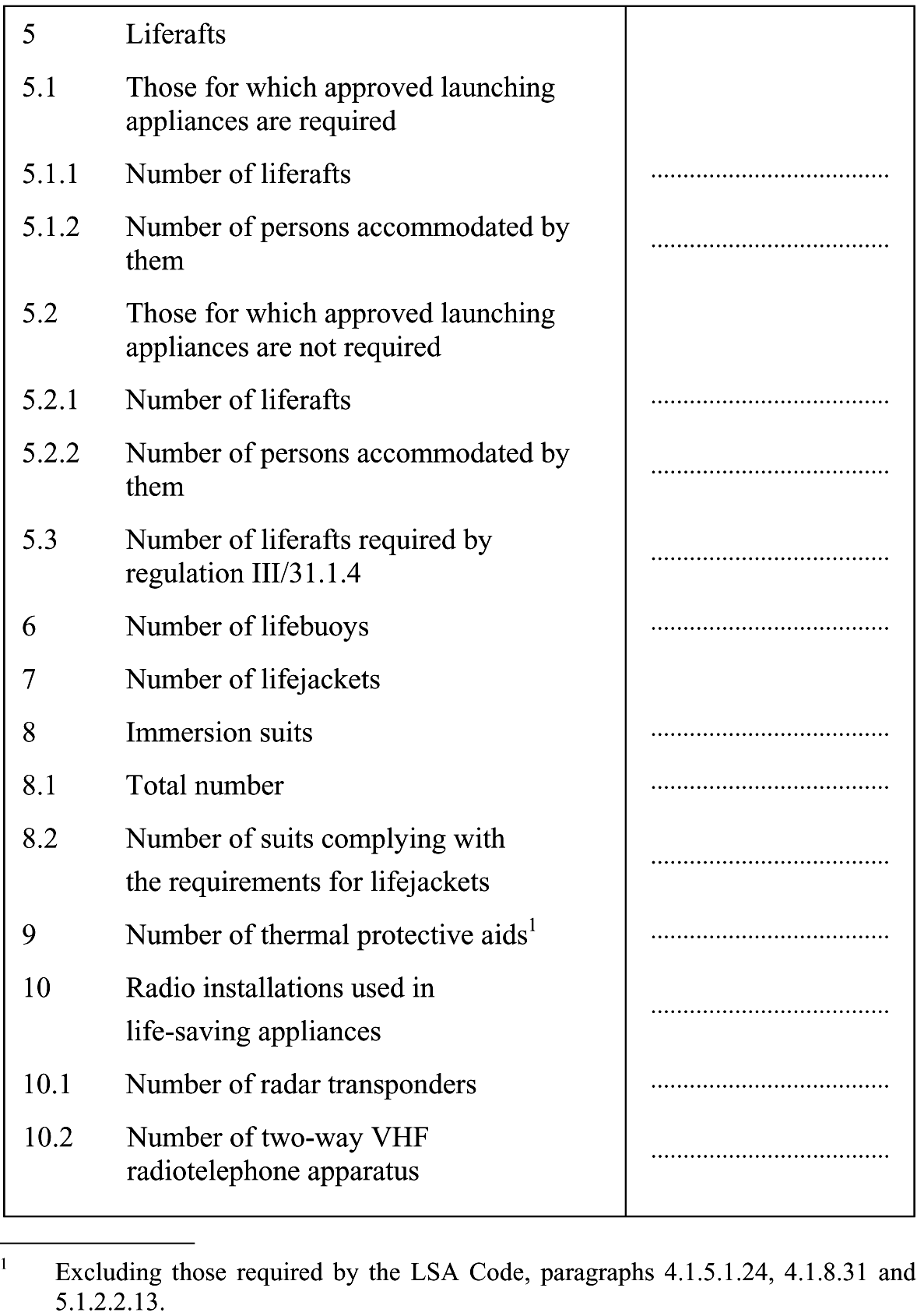

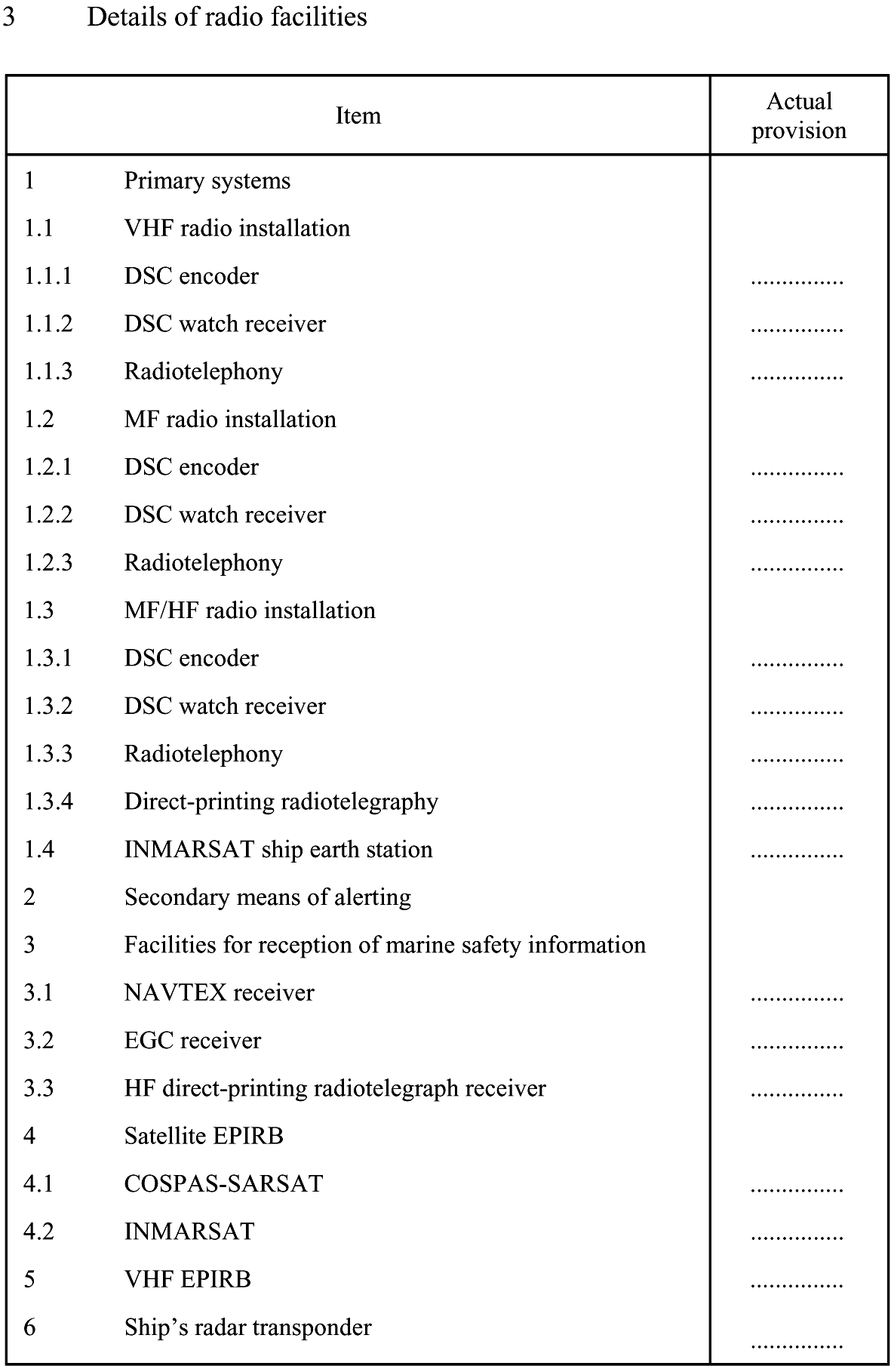

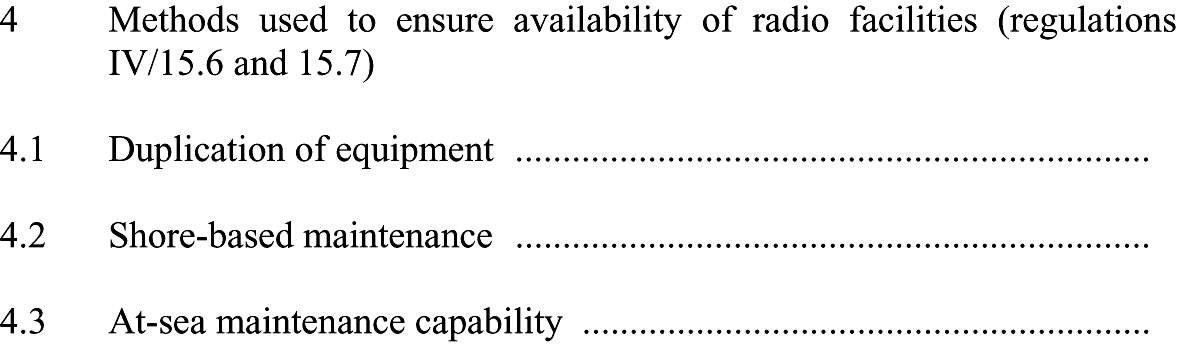

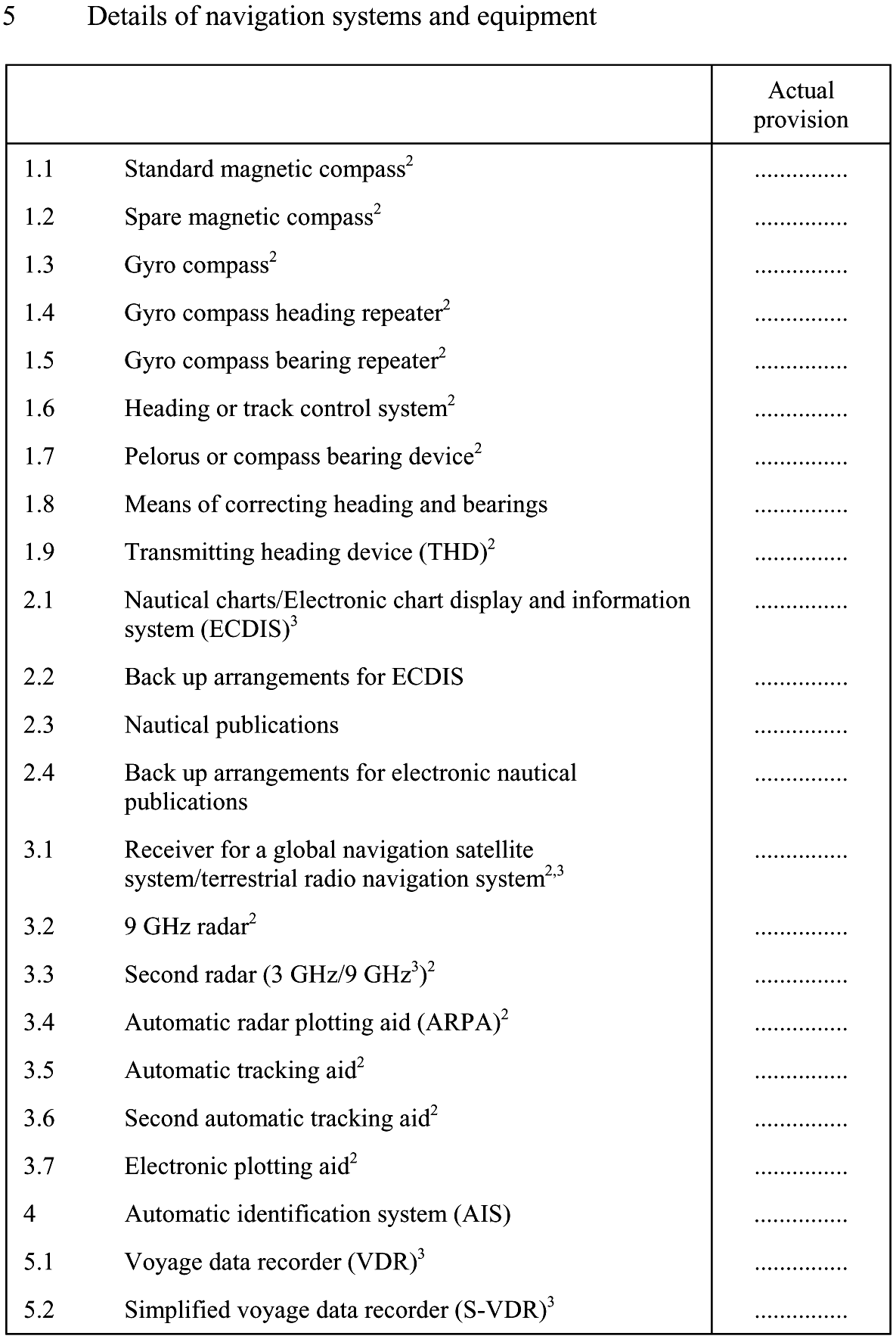

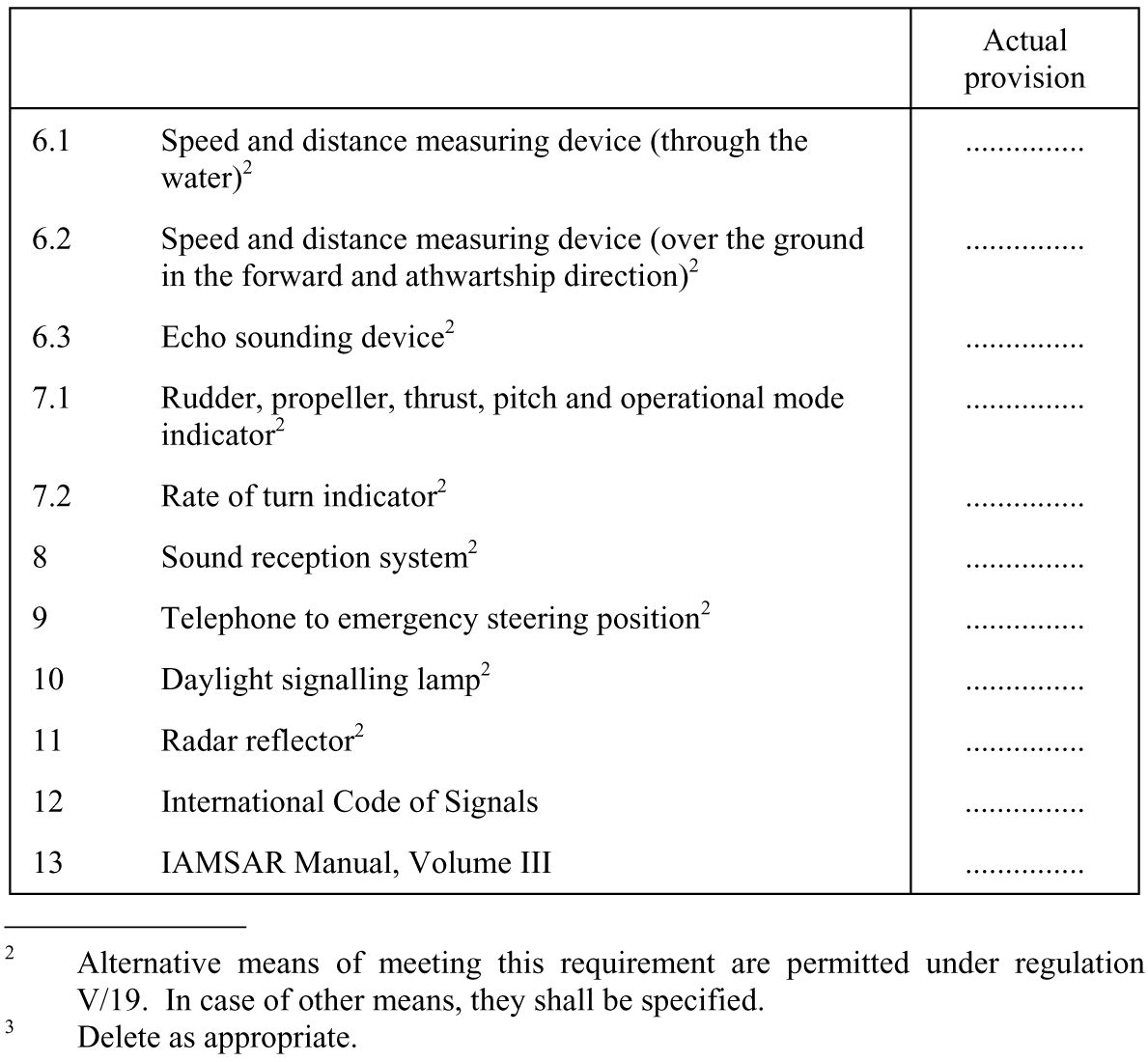

16. Existing section 3 is replaced by the following:

“3. Details of navigational systems and equipment

17. The following new section is inserted between the section commencing with the words “This certificate is valid until” and the section commencing with the words “Issued at”:

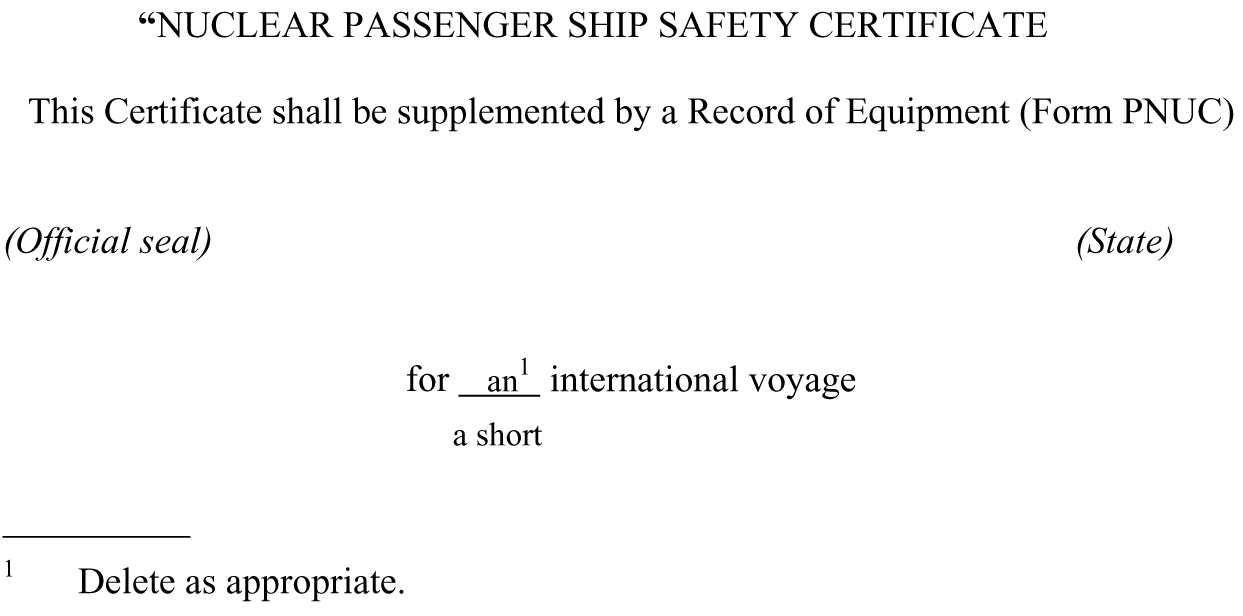

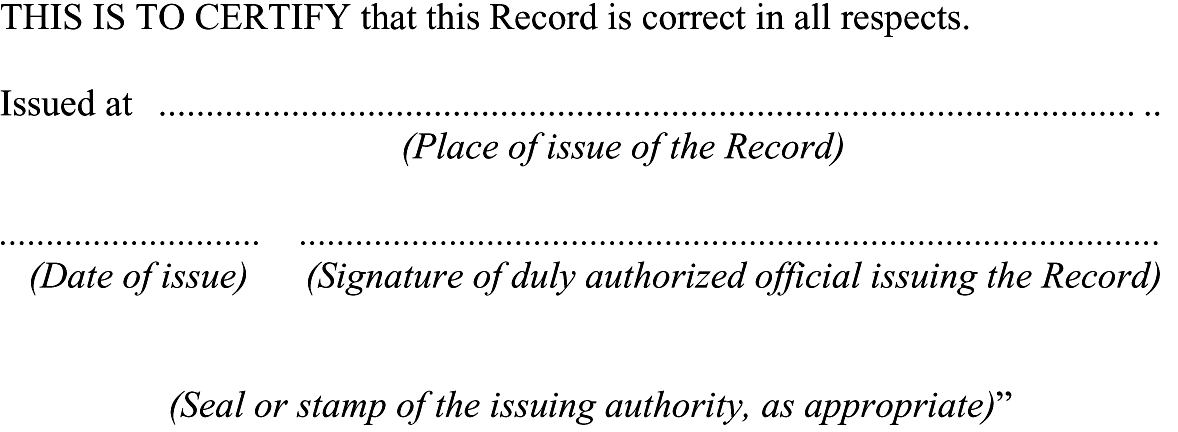

18. The existing form of the certificate is replaced by the following:

THIS IS TO CERTIFY:

1. That the ship has been surveyed in accordance with the requirements of regulation VIII/9 of the Convention.

2. That the ship, being a nuclear ship, complied with all the requirements of chapter VIII of the Convention and conformed to the Safety Assessment approved for the ship; and that:

2.1. the ship complied with the requirements of the Convention as regards:

.1. the structure, main and auxiliary machinery, boilers and other pressure vessels, including the nuclear propulsion plant and the collision protective structure;

.2. the watertight subdivision arrangements and details;

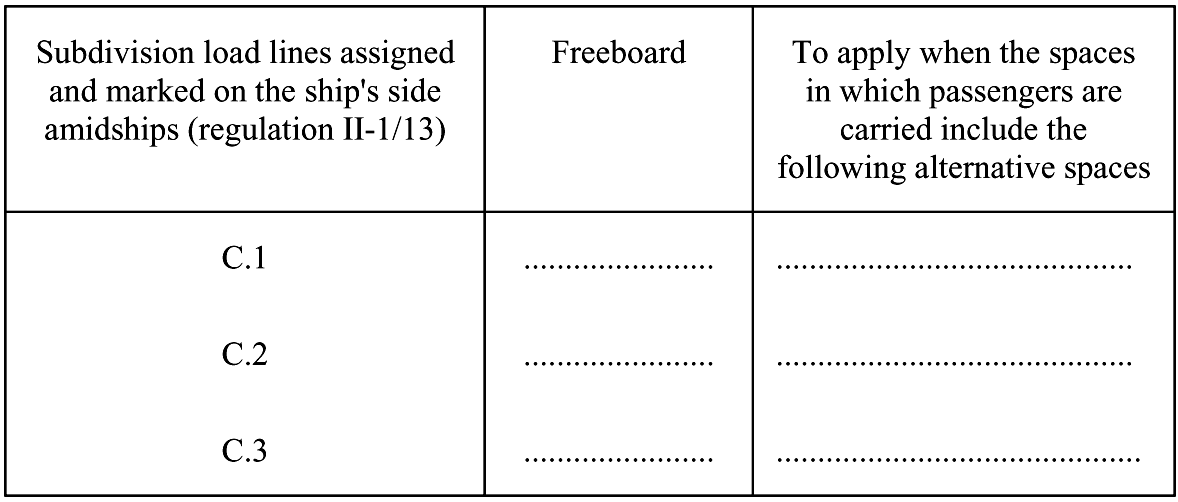

.3. the following subdivision load lines:

2.2. the ship complied with the requirements of the Convention as regards structural fire protection, fire safety systems and appliances and fire control plans;

2.3. the ship complied with the requirements of the Convention as regards radiation protection systems and equipment;

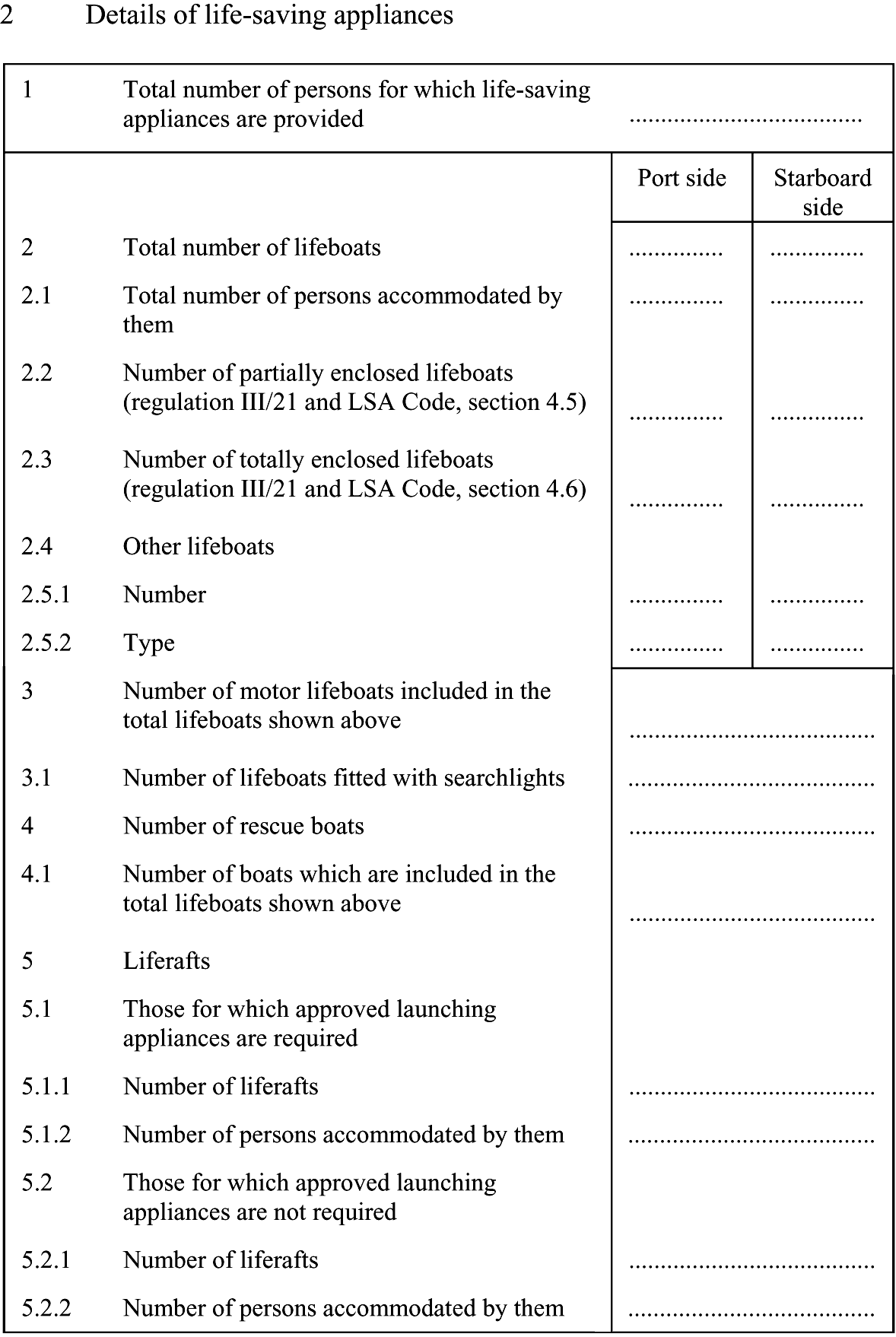

2.4. the life-saving appliances and the equipment of the lifeboats, liferafts and rescue boats were provided in accordance with the requirements of the Convention;

2.5. the ship was provided with a line-throwing appliance and radio installations used in life-saving appliances in accordance with the requirements of the Convention;

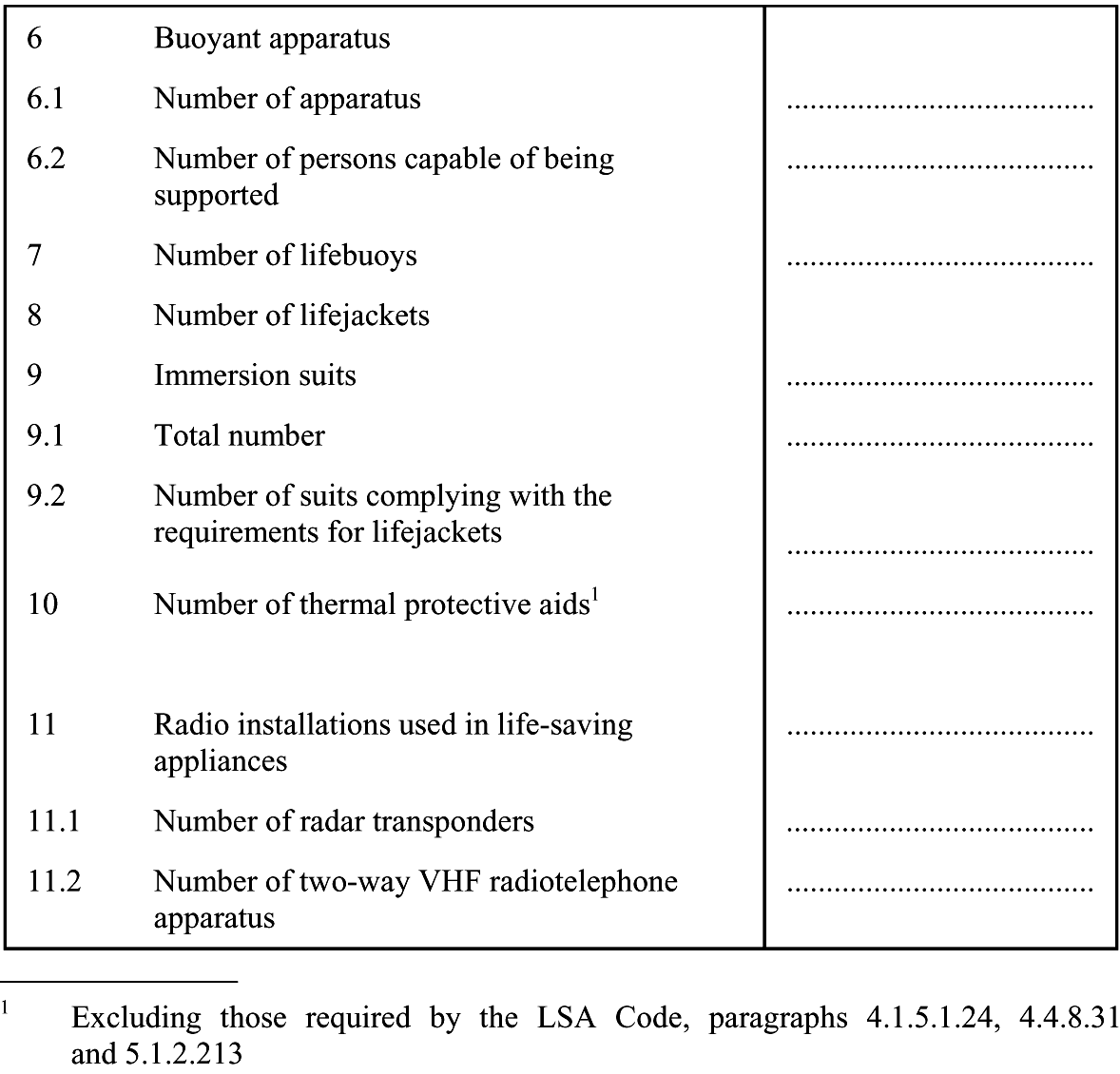

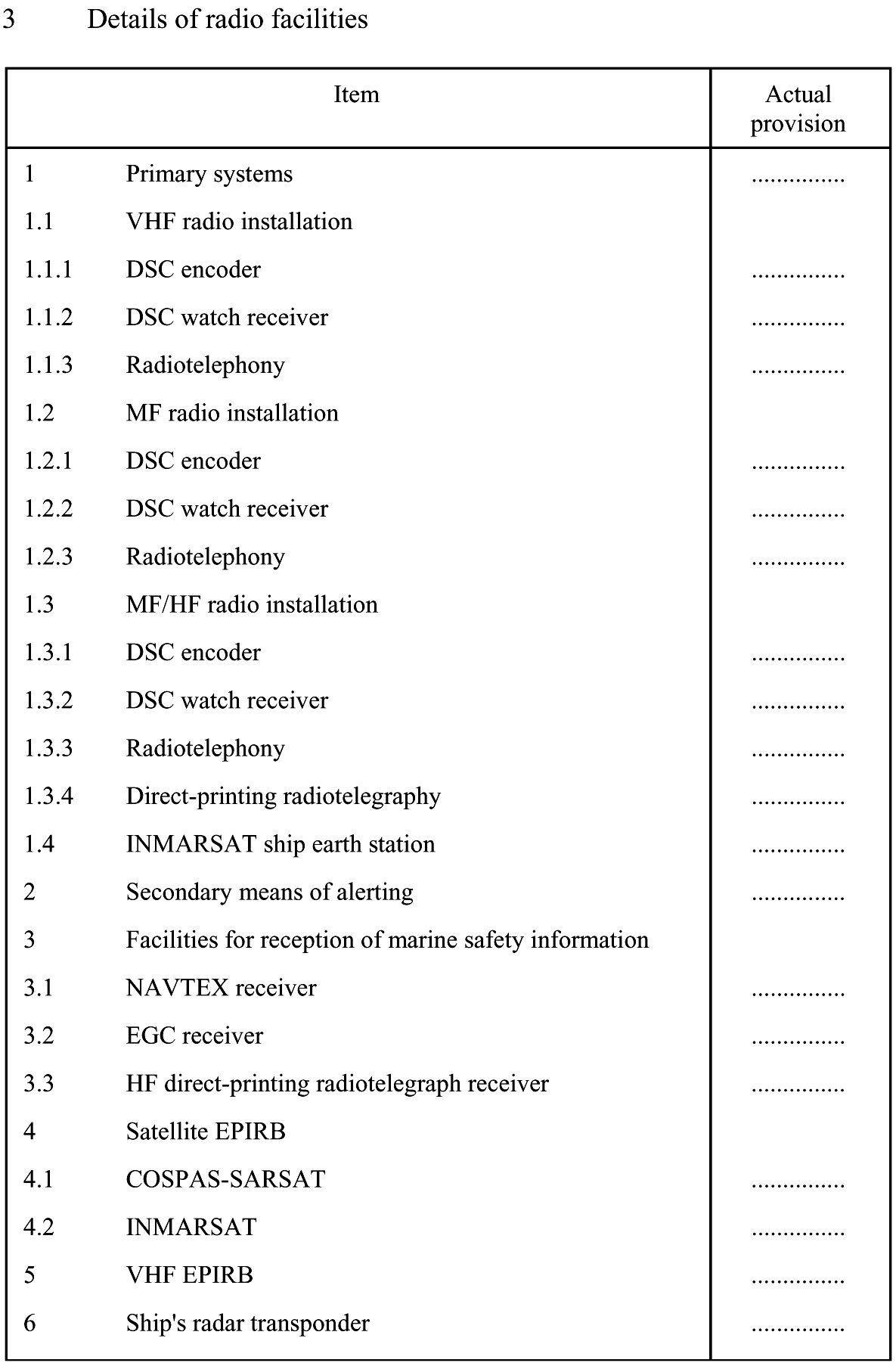

2.6. the ship complied with the requirements of the Convention as regards radio installations;

2.7. the functioning of the radio installations used in life-saving appliances complied with the requirements of the Convention;

2.8. the ship complied with the requirements of the Convention as regards shipborne navigational equipment, means of embarkation for pilots and nautical publications;

2.9. the ship was provided with lights, shapes, means of making sound signals and distress signals in accordance with the requirements of the Convention and the International Regulations for Preventing Collisions at Sea in force;

2.10. in all other respects the ship complied with the relevant requirements of the Convention.

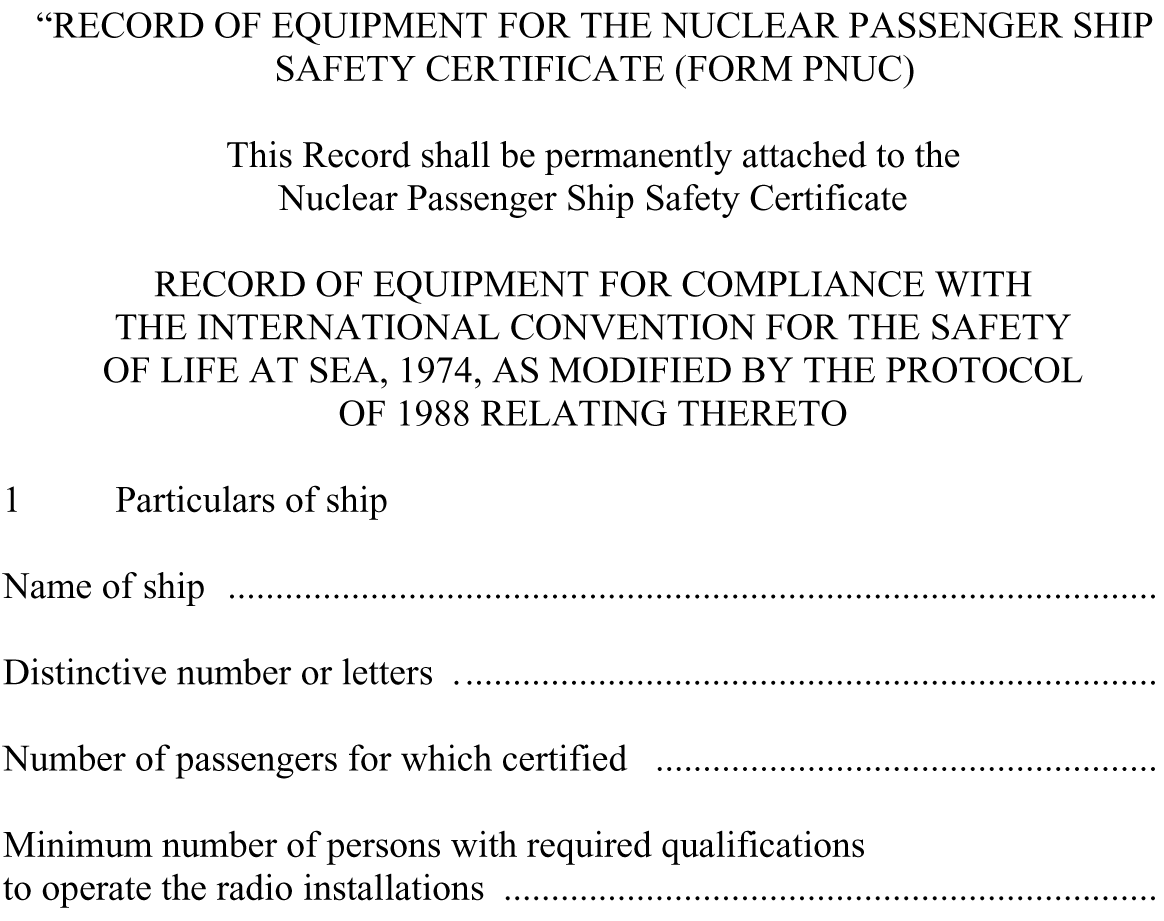

19. The following Record of Equipment for the Nuclear Passenger Ship Safety Certificate is added after the form of the Nuclear Passenger Ship Safety Certificate:

20. The existing form of the certificate is replaced by the following:

THIS IS TO CERTIFY:

1. That the ship has been surveyed in accordance with the requirements of regulation VIII/9 of the Convention.

2. That the ship, being a nuclear ship, complied with all the requirements of chapter VIII of the Convention and conformed to the Safety Assessment approved for the ship; and that:

2.1. the condition of the structure, machinery and equipment as defined in regulation I/10 (as applicable to comply with regulation VIII/9), including the nuclear propulsion plant and the collision protective structure, was satisfactory and the ship complied with the relevant requirements of chapter II-1 and chapter II-2 of the Convention (other than those relating to fire safety systems and appliances and fire control plans);

2.2. the ship complied with the requirements of the Convention as regards fire safety systems and appliances and fire control plans;

2.3. the life-saving appliances and the equipment of the lifeboats, liferafts and rescue boats were provided in accordance with the requirements of the Convention;

2.4. the ship was provided with a line-throwing appliance and radio installations used in life-saving appliances in accordance with the requirements of the Convention;

2.5. the ship complied with the requirements of the Convention as regards radio installations;

2.6. the functioning of the radio installations used in life-saving appliances complied with the requirements of the Convention;

2.7. the ship complied with the requirements of the Convention as regards shipborne navigational equipment, means of embarkation for pilots and nautical publications;

2.8. the ship was provided with lights, shapes, means of making sound signals and distress signals in accordance with the requirements of the Convention and the International Regulations for Preventing Collisions at Sea in force;

2.9. in all other respects the ship complied with the relevant requirements of the regulations, so far as these requirements apply thereto.

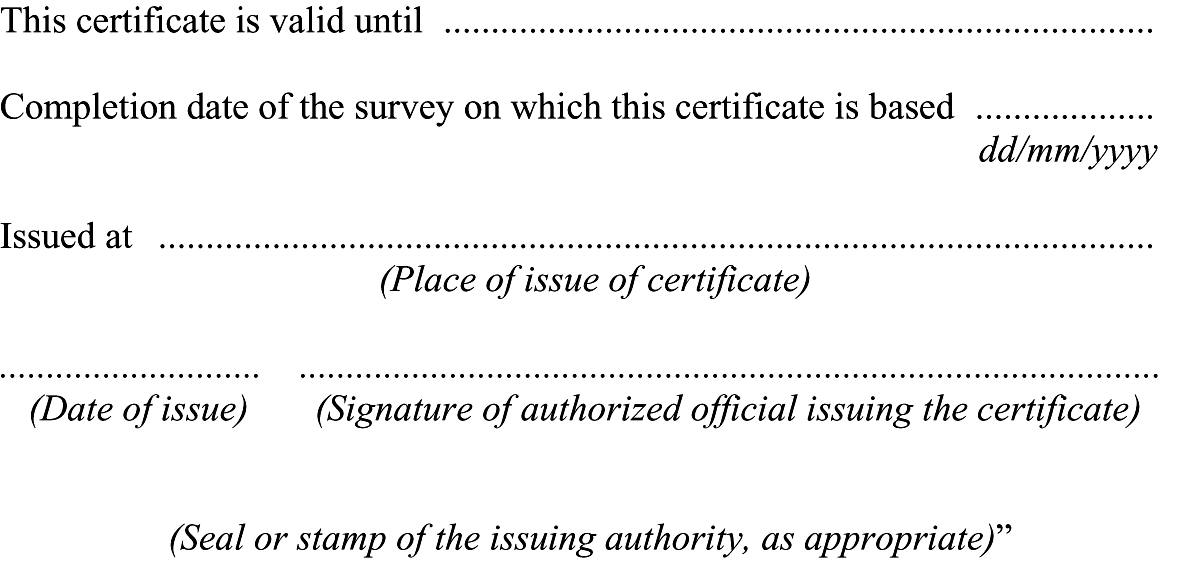

21. The following Record of Equipment for the Nuclear Cargo Ship Safety Certificate is added after the form of the Nuclear Cargo Ship Safety Certificate:

Resolutie MSC.194(80) van 20 mei 2005

Bij Resolutie MSC.194(80) heeft de Maritieme Veiligheidscommissie van de Internationale Maritieme Organisatie op 20 mei 2005 in overeenstemming met artikel VIII(b)(iv) van het Verdrag wijzigingen aangenomen. De Engelse tekst1) van de Resolutie en de wijzigingen luidt als volgt:

(adopted on 20 May 2005)

Adoption of Amendments to the International Convention for the Safety of Life at Sea, 1974, as amended

The Maritime Safety Committee,

Recalling Article 28(b) of the Convention on the International Maritime Organization concerning the functions of the Committee,

Recalling further article VIII(b) of the International Convention for the Safety of Life at Sea (SOLAS), 1974 (hereinafter referred to as .the Convention.), concerning the amendment procedure applicable to the Annex to the Convention, other than the provisions of chapter I thereof,

Having considered, at its eightieth session, amendments to the Convention, proposed and circulated in accordance with article VIII(b)(i) thereof,

1. Adopts, in accordance with article VIII(b)(iv) of the Convention, amendments to the Convention, the text of which is set out in the annexes to the present resolution;

2. Determines, in accordance with article VIII(b)(vi)(2)(bb) of the Convention, that:

a) the said amendments set out in annex 1 shall be deemed to have been accepted on 1 July 2006; and

b) the said amendments set out in annex 2 shall be deemed to have been accepted on 1 July 2008,

unless, prior to that date, more than one third of the Contracting Governments to the Convention or Contracting Governments the combined merchant fleets of which constitute not less than 50% of the gross tonnage of the world’s merchant fleet, have notified their objections to the amendments;

3. Invites SOLAS Contracting Governments to note that, in accordance with article VIII(b)(vii)(2) of the Convention:

a) the amendments set out in annex 1 shall enter into force on 1 January 2007; and

b) the amendments set out in annex 2 shall enter into force on 1 January 2009,

upon their acceptance in accordance with paragraph 2 above;

4. Requests the Secretary-General, in conformity with article VIII(b)(v) of the Convention, to transmit certified copies of the present resolution and the text of the amendments contained in the Annex to all Contracting Governments to the Convention;

5. Further requests the Secretary-General to transmit copies of this resolution and its Annex to Members of the Organization, which are not Contracting Governments to the Convention.

In addition to the requirements contained elsewhere in the present regulations, ships shall be designed, constructed and maintained in compliance with the structural, mechanical and electrical requirements of a classification society which is recognized by the Administration in accordance with the provisions of regulation XI-1/1, or with applicable national standards of the Administration which provide an equivalent level of safety.

(This regulation applies to oil tankers and bulk carriers constructed on or after 1 July 1998)

All dedicated seawater ballast tanks shall have an efficient corrosion prevention system, such as hard protective coatings or equivalent. The coatings should preferably be of a light colour. The scheme for the selection, application and maintenance of the system shall be approved by the Administration, based on the guidelines adopted by the Organization.1)

Where appropriate, sacrificial anodes shall also be used.

1. For the purpose of this regulation and regulation 3-4, tankers include oil tankers as defined in regulation 2, chemical tankers as defined in regulation VII/8.2 and gas carriers as defined in regulation VII/11.2.

2. Every tanker shall be provided with the means to enable the crew to gain safe access to the bow even in severe weather conditions. Such means of access shall be approved by the Administration based on the guidelines developed by the Organization.2)

1. Emergency towing arrangements shall be fitted at both ends on board every tanker of not less than 20,000 tonnes deadweight.

2. For tankers constructed on or after 1 July 2002:

.1. the arrangements shall, at all times, be capable of rapid deployment in the absence of main power on the ship to be towed and easy connection to the towing ship. At least one of the emergency towing arrangements shall be pre-rigged ready for rapid deployment; and

.2. emergency towing arrangements at both ends shall be of adequate strength taking into account the size and deadweight of the ship, and the expected forces during bad weather conditions. The design and construction and prototype testing of the emergency towing arrangements shall be approved by the Administration, based on the Guidelines developed by the Organization.

3. For tankers constructed before 1 July 2002, the design and construction of emergency towing arrangements shall be approved by the Administration, based on the Guidelines developed by the Organization.3)

1. This regulation shall apply to materials used for the structure, machinery, electrical installations and equipment covered by the present Convention.

2. For all ships, new installation of materials which contain asbestos shall be prohibited except for:

.1. vanes used in rotary vane compressors and rotary vane vacuum pumps;

.2. watertight joints and linings used for the circulation of fluids when, at high temperature (in excess of 350ºC) or pressure (in excess of 7 x 106 Pa), there is a risk of fire, corrosion or toxicity; and

.3. supple and flexible thermal insulation assemblies used for temperatures above 1000ºC.

1. Application

1.1. Except as provided for in paragraph 1.2, this regulation applies to oil tankers of 500 gross tonnage and over and bulk carriers, as defined in regulation IX/1, of 20,000 gross tonnage and over, constructed on or after 1 January 2006.

1.2. Oil tankers of 500 gross tonnage and over constructed on or after 1 October 1994 but before 1 January 2005 shall comply with the provisions of regulation II-1/12-2 adopted by resolution MSC.27(61).

2. Means of access to cargo and other spaces

2.1. Each space shall be provided with means of access to enable, throughout the life of a ship, overall and close-up inspections and thickness measurements of the ship’s structures to be carried out by the Administration, the company, as defined in regulation IX/1, and the ship.’s personnel and others as necessary. Such means of access shall comply with the requirements of paragraph 5 and with the Technical provisions for means of access for inspections, adopted by the Maritime Safety Committee by resolution MSC.133(76), as may be amended by the Organization, provided that such amendments are adopted, brought into force and take effect in accordance with the provisions of article VIII of the present Convention concerning the amendment procedures applicable to the Annex other than chapter I.

2.2. Where a permanent means of access may be susceptible to damage during normal cargo loading and unloading operations or where it is impracticable to fit permanent means of access, the Administration may allow, in lieu thereof, the provision of movable or portable means of access, as specified in the Technical provisions, provided that the means of attaching, rigging, suspending or supporting the portable means of access forms a permanent part of the ship’s structure. All portable equipment shall be capable of being readily erected or deployed by ship’s personnel.

2.3. The construction and materials of all means of access and their attachment to the ship’s structure shall be to the satisfaction of the Administration. The means of access shall be subject to survey prior to, or in conjunction with, its use in carrying out surveys in accordance with regulation I/10.

3. Safe access to cargo holds, cargo tanks, ballast tanks and other spaces

3.1. Safe access4) to cargo holds, cofferdams, ballast tanks, cargo tanks and other spaces in the cargo area shall be direct from the open deck and such as to ensure their complete inspection. Safe access to double bottom spaces or to forward ballast tanks may be from a pump-room, deep cofferdam, pipe tunnel, cargo hold, double hull space or similar compartment not intended for the carriage of oil or hazardous cargoes.

3.2. Tanks, and subdivisions of tanks, having a length of 35 m or more, shall be fitted with at least two access hatchways and ladders, as far apart as practicable. Tanks less than 35 m in length shall be served by at least one access hatchway and ladder. When a tank is subdivided by one or more swash bulkheads or similar obstructions which do not allow ready means of access to the other parts of the tank, at least two hatchways and ladders shall be fitted.

3.3. Each cargo hold shall be provided with at least two means of access as far apart as practicable. In general, these accesses should be arranged diagonally, for example one access near the forward bulkhead on the port side, the other one near the aft bulkhead on the starboard side.

4. Ship structure access manual

4.1. A ship’s means of access to carry out overall and close-up inspections and thickness measurements shall be described in a Ship structure access manual approved by the Administration, an updated copy of which shall be kept on board. The Ship structure access manual shall include the following for each space:

.1. plans showing the means of access to the space, with appropriate technical specifications and dimensions;

.2. plans showing the means of access within each space to enable an overall inspection to be carried out, with appropriate technical specifications and dimensions. The plans shall indicate from where each area in the space can be inspected;

.3. plans showing the means of access within the space to enable close-up inspections to be carried out, with appropriate technical specifications and dimensions. The plans shall indicate the positions of critical structural areas, whether the means of access is permanent or portable and from where each area can be inspected;

.4. instructions for inspecting and maintaining the structural strength of all means of access and means of attachment, taking into account any corrosive atmosphere that may be within the space;

.5. instructions for safety guidance when rafting is used for close-up inspections and thickness measurements;

.6. instructions for the rigging and use of any portable means of access in a safe manner;

.7. an inventory of all portable means of access; and

.8. records of periodical inspections and maintenance of the ship’s means of access.

4.2. For the purpose of this regulation .critical structural areas. are locations which have been identified from calculations to require monitoring or from the service history of similar or sister ships to be sensitive to cracking, buckling, deformation or corrosion which would impair the structural integrity of the ship.

5. General technical specifications

5.1. For access through horizontal openings, hatches or manholes, the dimensions shall be sufficient to allow a person wearing a self-contained air-breathing apparatus and protective equipment to ascend or descend any ladder without obstruction and also provide a clear opening to facilitate the hoisting of an injured person from the bottom of the space. The minimum clear opening shall not be less than 600 mm x 600 mm. When access to a cargo hold is arranged through the cargo hatch, the top of the ladder shall be placed as close as possible to the hatch coaming. Access hatch coamings having a height greater than 900 mm shall also have steps on the outside in conjunction with the ladder.

5.2. For access through vertical openings, or manholes, in swash bulkheads, floors, girders and web frames providing passage through the length and breadth of the space, the minimum opening shall be not less than 600 mm x 800 mm at a height of not more than 600 mm from the bottom shell plating unless gratings or other foot holds are provided.

5.3. For oil tankers of less than 5,000 tonnes deadweight, the Administration may approve, in special circumstances, smaller dimensions for the openings referred to in paragraphs 5.1 and 5.2, if the ability to traverse such openings or to remove an injured person can be proved to the satisfaction of the Administration.

1. A set of as-built construction drawings5) and other plans showing any subsequent structural alterations shall be kept on board a ship constructed on or after 1 January 2007.

2. An additional set of such drawings shall be kept ashore by the Company, as defined in regulation IX/1.2.

1. This regulation applies to ships constructed on or after 1 January 2007, but does not apply to emergency towing arrangements provided in accordance with regulation 3-4.

2. Ships shall be provided with arrangements, equipment and fittings of sufficient safe working load to enable the safe conduct of all towing and mooring operations associated with the normal operation of the ship.

3. Arrangements, equipment and fittings provided in accordance with paragraph 2 shall meet the appropriate requirements of the Administration or an organization recognized by the Administration under regulation I/6.6)

4. Each fitting or item of equipment provided under this regulation shall be clearly marked with any restrictions associated with its safe operation, taking into account the strength of its attachment to the ship’s structure.”

3. The following new regulation 23-3 is added after existing regulation 23-2:

1. Single hold cargo ships other than bulk carriers constructed before 1 January 2007 shall comply with the requirements of this regulation not later than the date of the first intermediate or renewal survey of the ship to be carried out after 1 January 2007, whichever comes first.

2. For the purpose of this regulation, freeboard deck has the meaning defined in the International Convention on Load Lines in force.

3. Ships having a length (L) of less than 80 m, or 100 m if constructed before 1 July 1998, and a single cargo hold below the freeboard deck or cargo holds below the freeboard deck which are not separated by at least one bulkhead made watertight up to that deck, shall be fitted in such space or spaces with water level detectors7) .

4. The water level detectors required by paragraph 3 shall:

.1. give an audible and visual alarm at the navigation bridge when the water level above the inner bottom in the cargo hold reaches a height of not less than 0.3 m, and another when such level reaches not more than 15% of the mean depth of the cargo hold; and

.2. be fitted at the aft end of the hold, or above its lowest part where the inner bottom is not parallel to the designed waterline. Where webs or partial watertight bulkheads are fitted above the inner bottom, Administrations may require the fitting of additional detectors.

5. The water level detectors required by paragraph 3 need not be fitted in ships complying with regulation XII/12, or in ships having watertight side compartments each side of the cargo hold length extending vertically at least from inner bottom to freeboard deck.”

1. The existing paragraph 2.10 is deleted.

2. The following new paragraph 6 is added after the existing paragraph 5:

“6. Ships constructed on or after 1 July 2004 shall comply with the requirements of paragraphs 1 to 5, as amended, as follows:

.1. a new subparagraph .10 is added to paragraph 2 to read as follows:

“.10. automation systems shall be designed in a manner which ensures that threshold warning of impending or imminent slowdown or shutdown of the propulsion system is given to the officer in charge of the navigational watch in time to assess navigational circumstances in an emergency. In particular, the systems shall control, monitor, report, alert and take safety action to slow down or stop propulsion while providing the officer in charge of the navigational watch an opportunity to manually intervene, except for those cases where manual intervention will result in total failure of the engine and/or propulsion equipment within a short time, for example in the case of overspeed.””

1. The existing text of parts A, B and B-1 of the chapter is replaced by the following:

1.1. Unless expressly provided otherwise, this chapter shall apply to ships the keels of which are laid or which are at a similar stage of construction on or after 1 January 2009.

1.2. For the purpose of this chapter, the term a similar stage of construction means the stage at which:

.1. construction identifiable with a specific ship begins; and

.2. assembly of that ship has commenced comprising at least 50 tonnes or one per cent of the estimated mass of all structural material, whichever is less.

1.3. For the purpose of this chapter:

.1. the expression ships constructed means ships the keels of which are laid or which are at a similar stage of construction;

.2. the expression all ships means ships constructed before, on or after 1 January 2009;

.3. a cargo ship, whenever built, which is converted to a passenger ship shall be treated as a passenger ship constructed on the date on which such a conversion commences;

.4. the expression alterations and modifications of a major character means, in the context of cargo ship subdivision and stability, any modification to the construction which affects the level of subdivision of that ship. Where a cargo ship is subject to such modification, it shall be demonstrated that the A/R ratio calculated for the ship after such modifications is not less than the A/R ratio calculated for the ship before the modification.

However, in those cases where the ship’s A/R ratio before modification is equal to or greater than unity, it is only necessary that the ship after modification has an A value which is not less than R, calculated for the modified ship.

2. Unless expressly provided otherwise, for ships constructed before 1 January 2009, the Administration shall ensure that the requirements which are applicable under chapter II-1 of the International Convention for the Safety of Life at Sea, 1974, as amended by resolutions MSC.1(XLV), MSC.6(48), MSC.11(55), MSC.12(56), MSC.13(57), MSC.19(58), MSC.26(60), MSC.27(61), Resolution 1 of the 1995 SOLAS Conference, MSC.47(66), MSC.57(67), MSC.65(68), MSC.69(69), MSC.99(73), MSC.134(76), MSC.151(78) and MSC.170(79) are complied with.

3. All ships which undergo repairs, alterations, modifications and outfitting related thereto shall continue to comply with at least the requirements previously applicable to these ships. Such ships, if constructed before the date on which any relevant amendments enter into force, shall, as a rule, comply with the requirements for ships constructed on or after that date to at least the same extent as they did before undergoing such repairs, alterations, modifications or outfitting. Repairs, alterations and modifications of a major character and outfitting related thereto shall meet the requirements for ships constructed on or after the date on which any relevant amendments enter into force, in so far as the Administration deems reasonable and practicable.

4. The Administration of a State may, if it considers that the sheltered nature and conditions of the voyage are such as to render the application of any specific requirements of this chapter unreasonable or unnecessary, exempt from those requirements individual ships or classes of ships entitled to fly the flag of that State which, in the course of their voyage, do not proceed more than 20 miles from the nearest land.

5. In the case of passenger ships which are employed in special trades for the carriage of large numbers of special trade passengers, such as the pilgrim trade, the Administration of the State whose flag such ships are entitled to fly, if satisfied that it is impracticable to enforce compliance with the requirements of this chapter, may exempt such ships from those requirements, provided that they comply fully with the provisions of:

.1. the rules annexed to the Special Trade Passenger Ships Agreement, 1971; and

.2. the rules annexed to the Protocol on Space Requirements for Special Trade Passenger Ships, 1973.

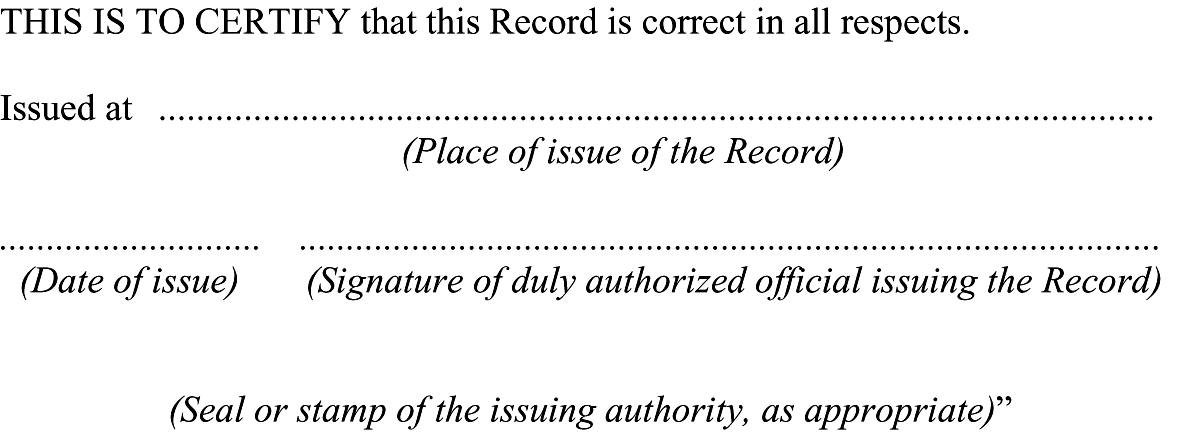

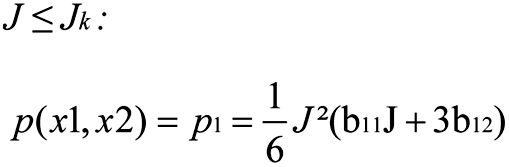

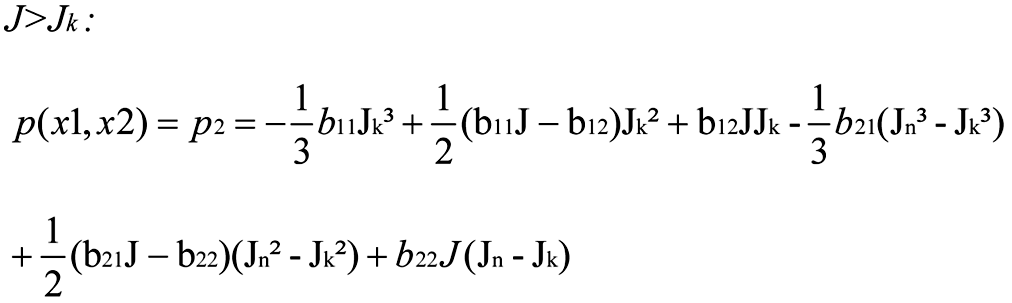

For the purpose of this chapter, unless expressly provided otherwise:

1. Subdivision length (Ls) of the ship is the greatest projected moulded length of that part of the ship at or below deck or decks limiting the vertical extent of flooding with the ship at the deepest subdivision draught.

2. Mid-length is the mid-point of the subdivision length of the ship.

3. Aft terminal is the aft limit of the subdivision length.

4. Forward terminal is the forward limit of the subdivision length.

5. Length (L) is the length as defined in the International Convention on Load Lines in force.

6. Freeboard deck is the deck as defined in the International Convention on Load Lines in force.

7. Forward perpendicular is the forward perpendicular as defined in the International Convention on Load Lines in force.

8. Breadth (B) is the greatest moulded breadth of the ship at or below the deepest subdivision draught.

9. Draught (d) is the vertical distance from the keel line at mid-length to the waterline in question.

10. Deepest subdivision draught (ds) is the waterline which corresponds to the summer load line draught of the ship.

11. Light service draught (dl) is the service draught corresponding to the lightest anticipated loading and associated tankage, including, however, such ballast as may be necessary for stability and/or immersion. Passenger ships should include the full complement of passengers and crew on board.

12. Partial subdivision draught (dp) is the light service draught plus 60% of the difference between the light service draught and the deepest subdivision draught.

13. Trim is the difference between the draught forward and the draught aft, where the draughts are measured at the forward and aft terminals respectively, disregarding any rake of keel.

14. Permeability (μ) of a space is the proportion of the immersed volume of that space which can be occupied by water.

15. Machinery spaces are spaces between the watertight boundaries of a space containing the main and auxiliary propulsion machinery, including boilers, generators and electric motors primarily intended for propulsion. In the case of unusual arrangements, the Administration may define the limits of the machinery spaces.

16. Weathertight means that in any sea conditions water will not penetrate into the ship.

17. Watertight means having scantlings and arrangements capable of preventing the passage of water in any direction under the head of water likely to occur in intact and damaged conditions. In the damaged condition, the head of water is to be considered in the worst situation at equilibrium, including intermediate stages of flooding.

18. Design pressure means the hydrostatic pressure for which each structure or appliance assumed watertight in the intact and damage stability calculations is designed to withstand.

19. Bulkhead deck in a passenger ship means the uppermost deck at any point in the subdivision length (Ls ) to which the main bulkheads and the ship’s shell are carried watertight and the lowermost deck from which passenger and crew evacuation will not be impeded by water in any stage of flooding for damage cases defined in regulation 8 and in part B-2 of this chapter. The bulkhead deck may be a stepped deck. In a cargo ship the freeboard deck may be taken as the bulkhead deck.

20. Deadweight is the difference in tonnes between the displacement of a ship in water of a specific gravity of 1.025 at the draught corresponding to the assigned summer freeboard and the lightweight of the ship.

21. Lightweight is the displacement of a ship in tonnes without cargo, fuel, lubricating oil, ballast water, fresh water and feedwater in tanks, consumable stores, and passengers and crew and their effects.

22. Oil tanker is the oil tanker defined in regulation 1 of Annex 1 of the Protocol of 1978 relating to the International Convention for the Prevention of Pollution from Ships, 1973.

23. Ro-ro passenger ship means a passenger ship with ro-ro spaces or special category spaces as defined in regulation II-2/3.

24. Bulk carrier means a bulk carrier as defined in regulation XII/1.1.

25. Keel line is a line parallel to the slope of the keel passing amidships through:

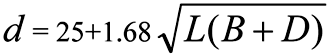

.1. the top of the keel at centreline or line of intersection of the inside of shell plating with the keel if a bar keel extends below that line, on a ship with a metal shell; or